Hello Tushy

Position: Product Engineer

Role: Research, Design, Packaging, Prototyping & Validation

Project Timeline: Jan 2023 - Jul 2023

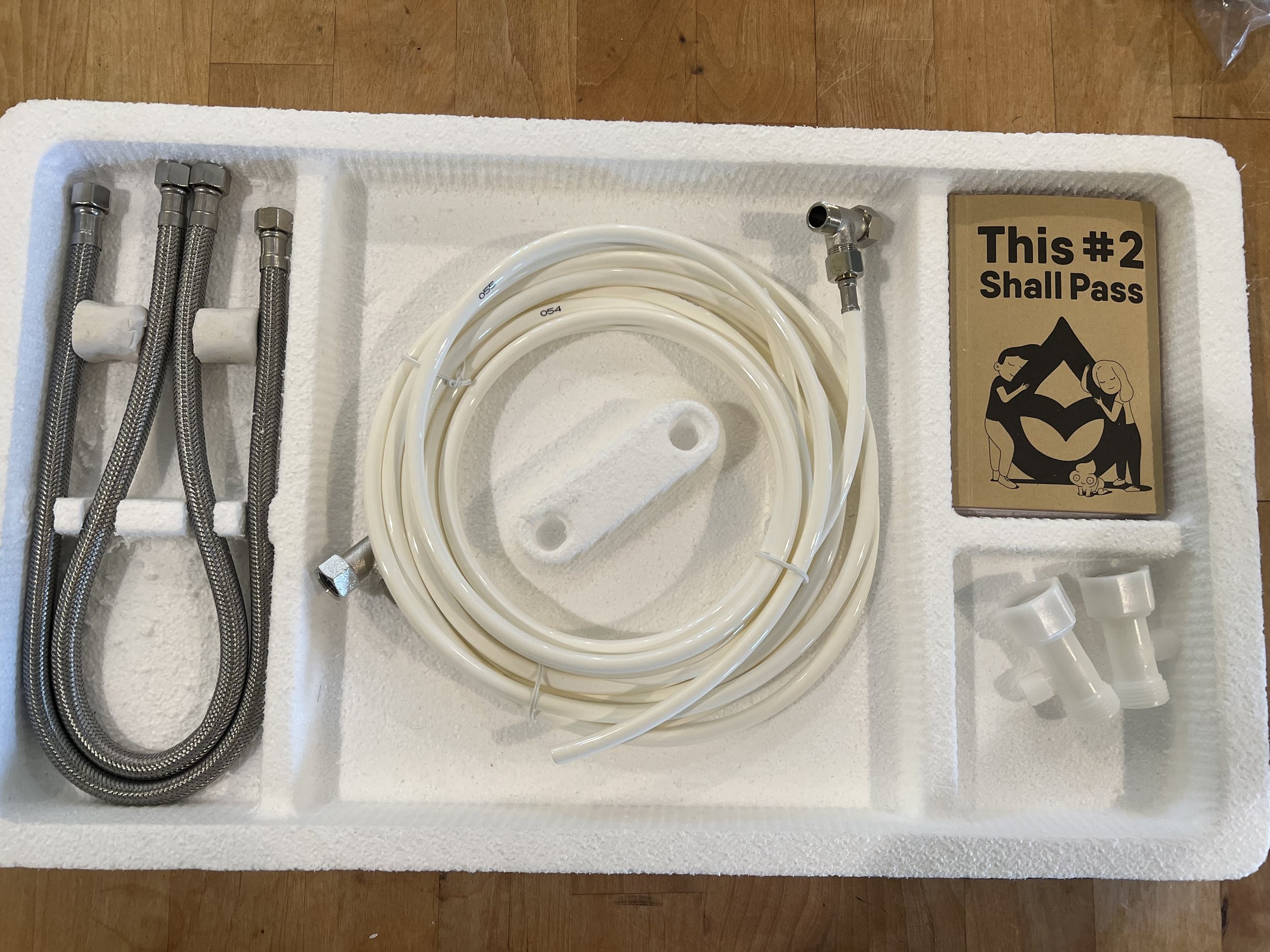

Bidet 2 Pack

The 2 pack is a molded pulp packaging configuration that consolidates two bidet attachments in one box.

Customers frequently ordered 2 bidets at once, often incentivized by website promotions. In an effort to reduce packaging and freight costs along with reducing wasteful material it was an obvious decision to create a 2 pack.

Design and Prototyping

Product Design Requirements:

Maintains design language and aesthetic from single bidet packaging

Provides sufficient protection

Molded pulp design

Cost efficient

Satisfying unboxing experience

Layout and Orientation

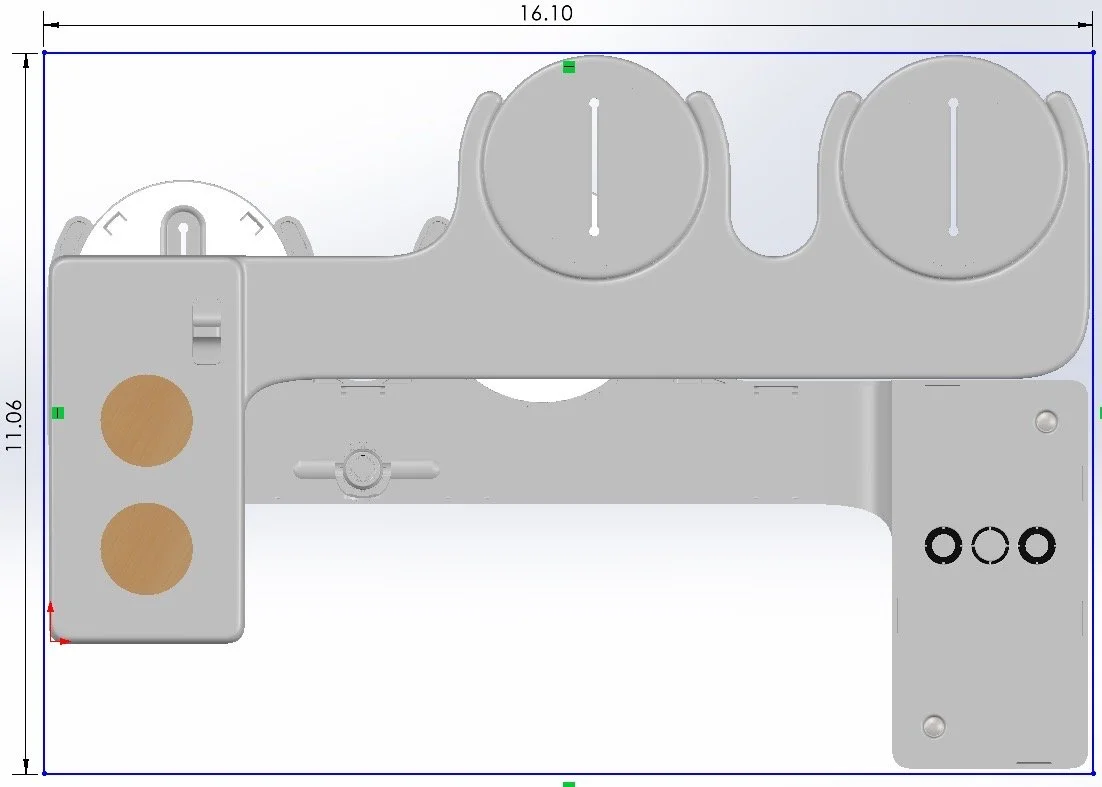

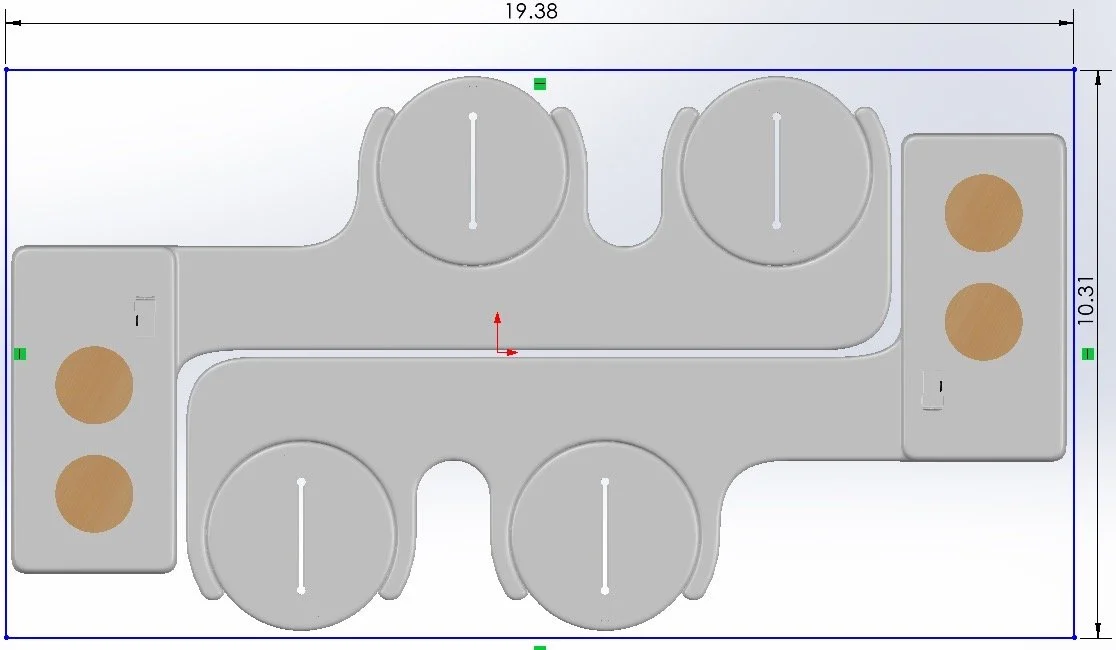

The first step of the project was determining the layout and orientation of the 2 bidets. This was done in consideration of packing efficiency, aesthetic, and feasibility. To select the layout, various configurations were made in SolidWorks. Using the boundary box feature, the total volume was able to be calculated. As a sanity check, the layouts were tested in a rudimentary physical fashion.

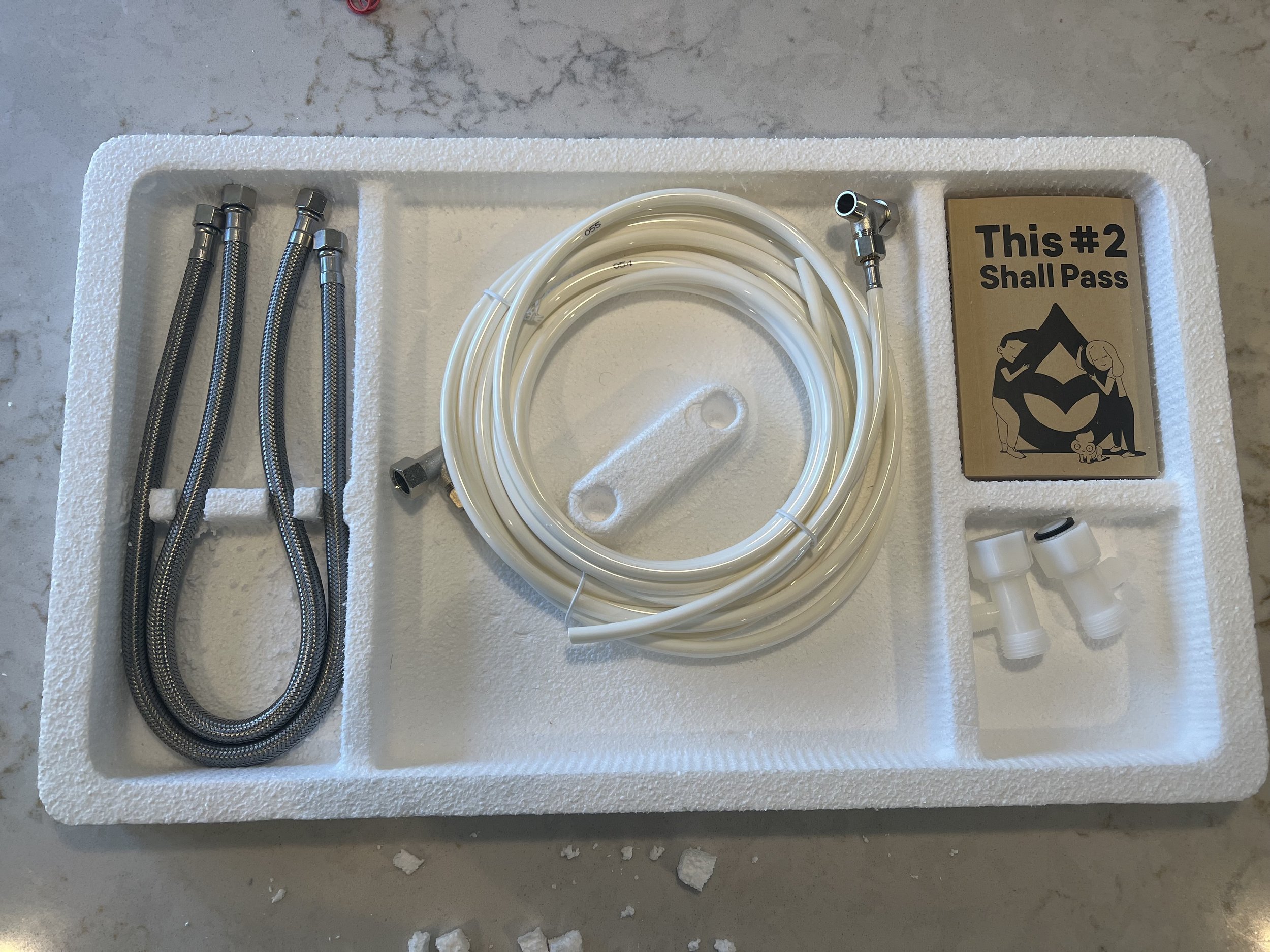

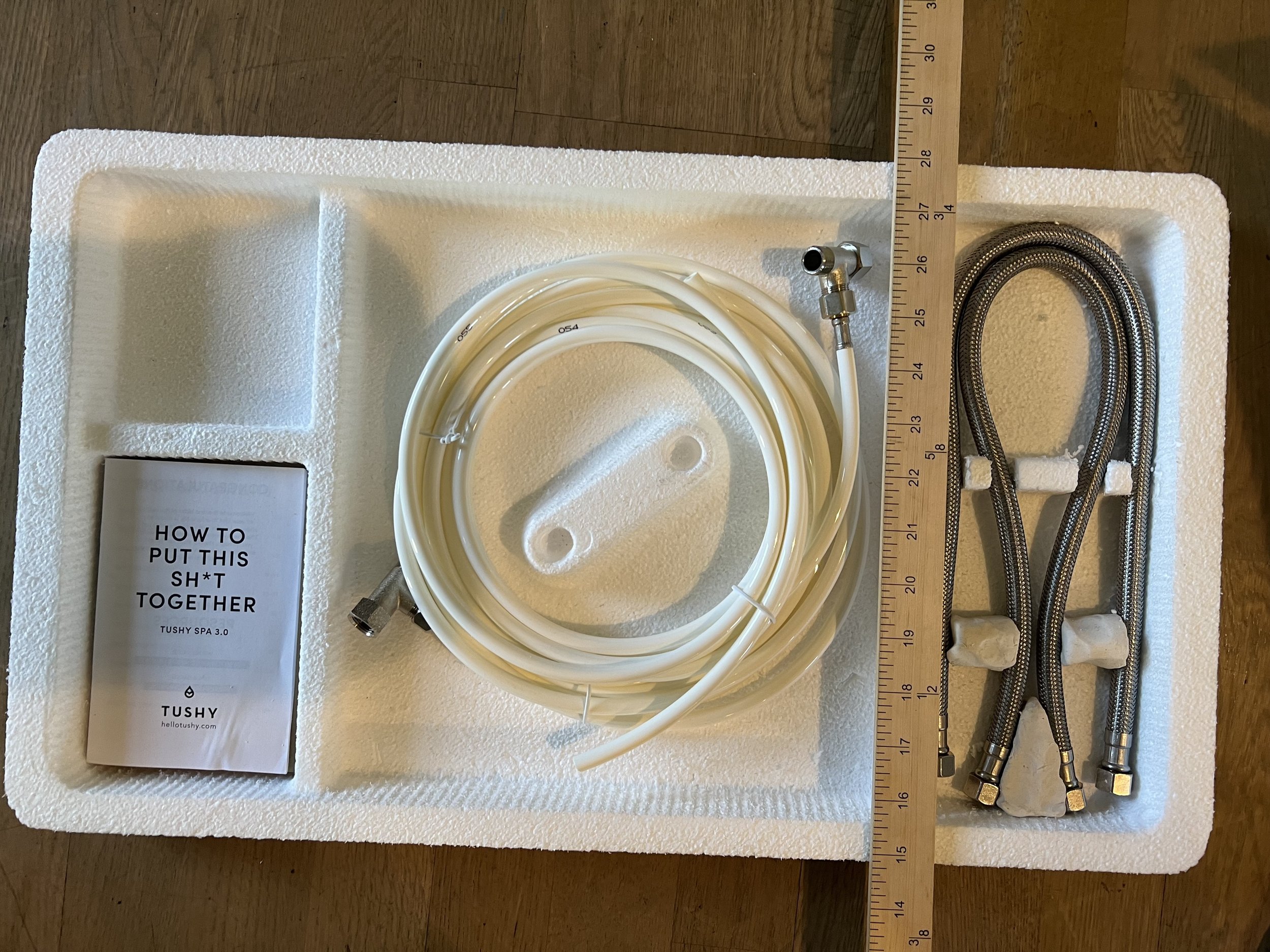

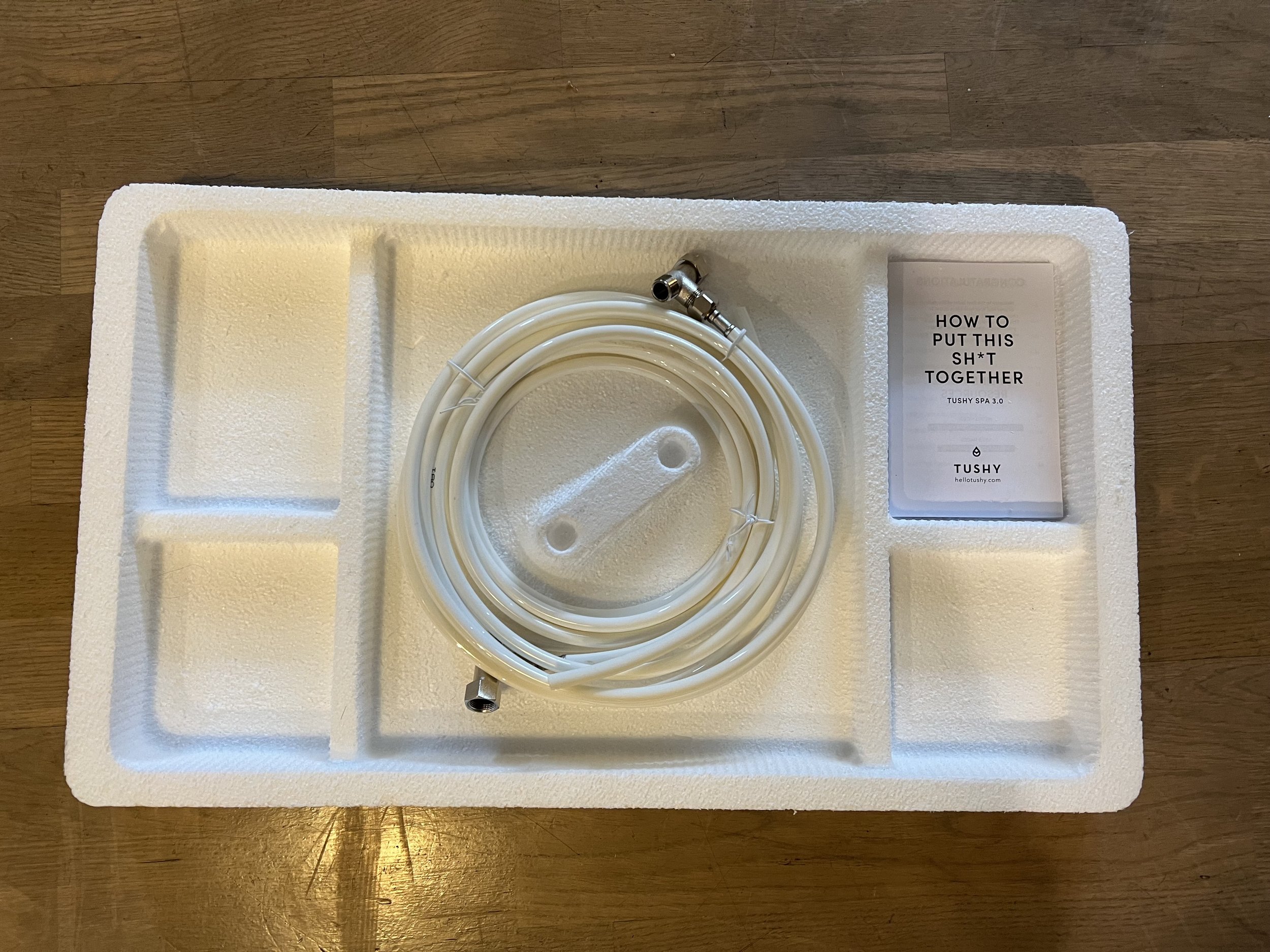

3D Modeling

After determining that the interlocking layout is both the most efficient and aesthetically pleasing orientation, I modeled the molded pulp design in SolidWorks. Here, I was able determine the spacing and layout of the accessories. These design files allowed us to get tooling, production, and freight quotes, which was well below the cost of shipping 2 separate bidets.

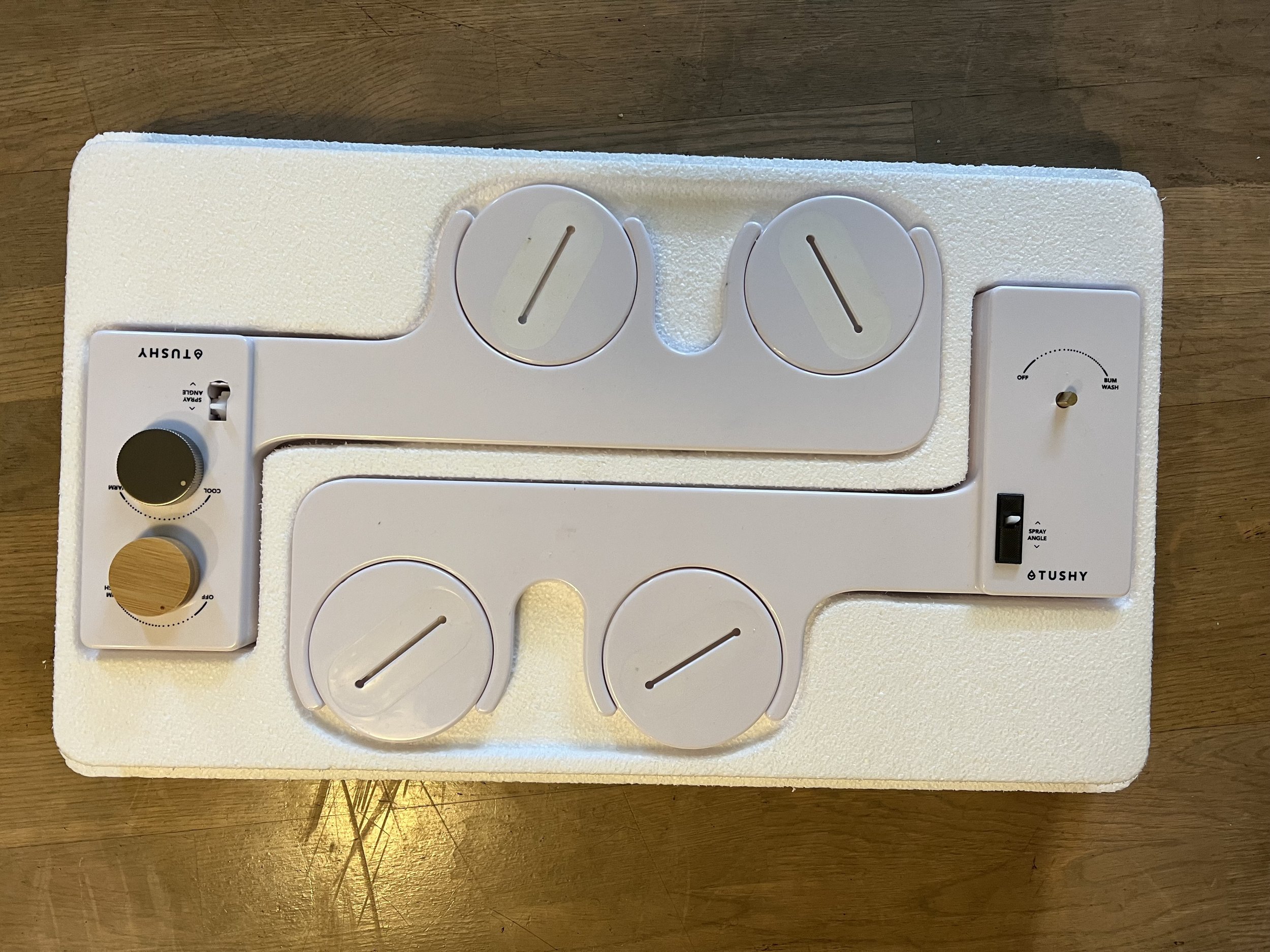

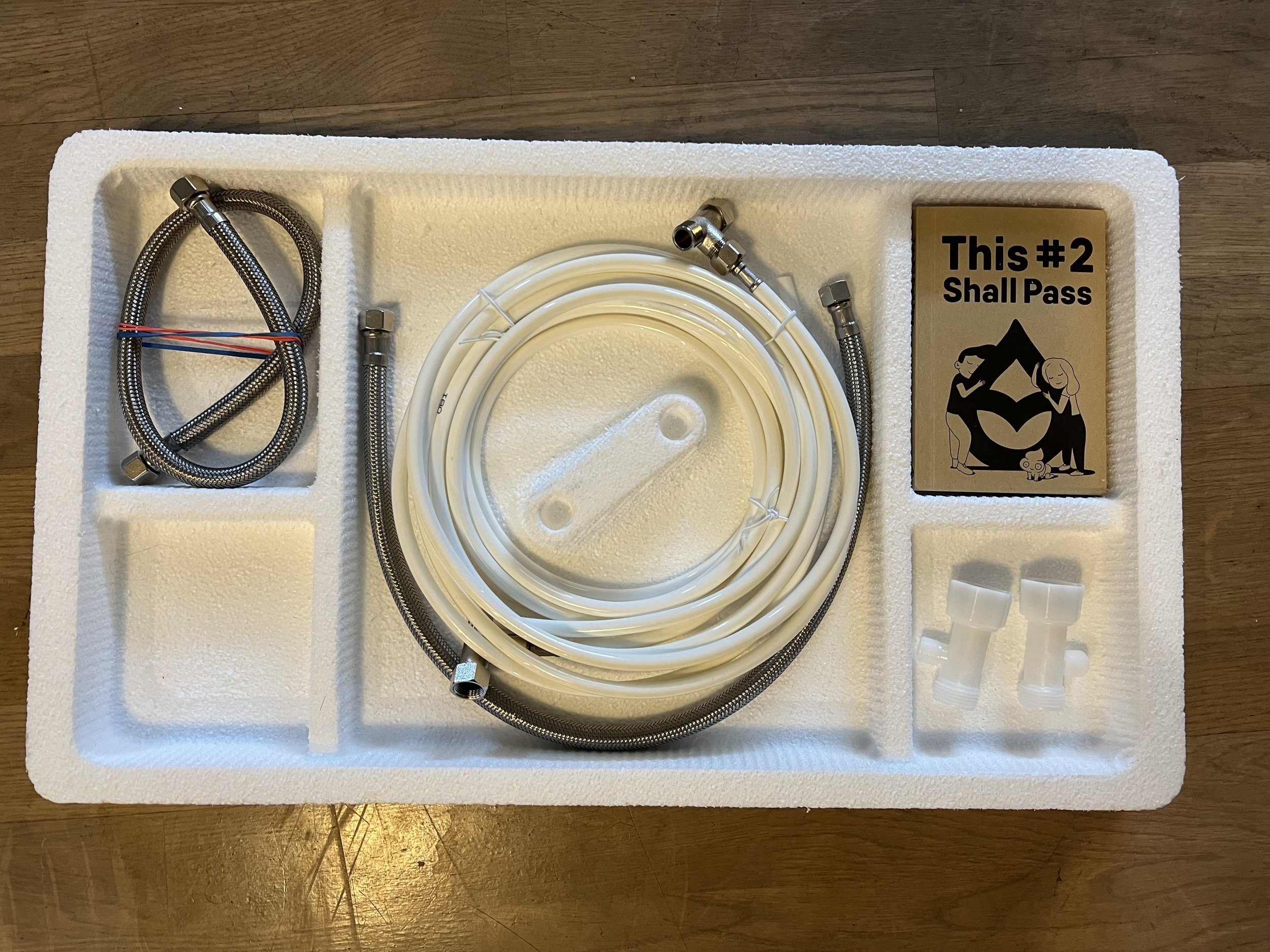

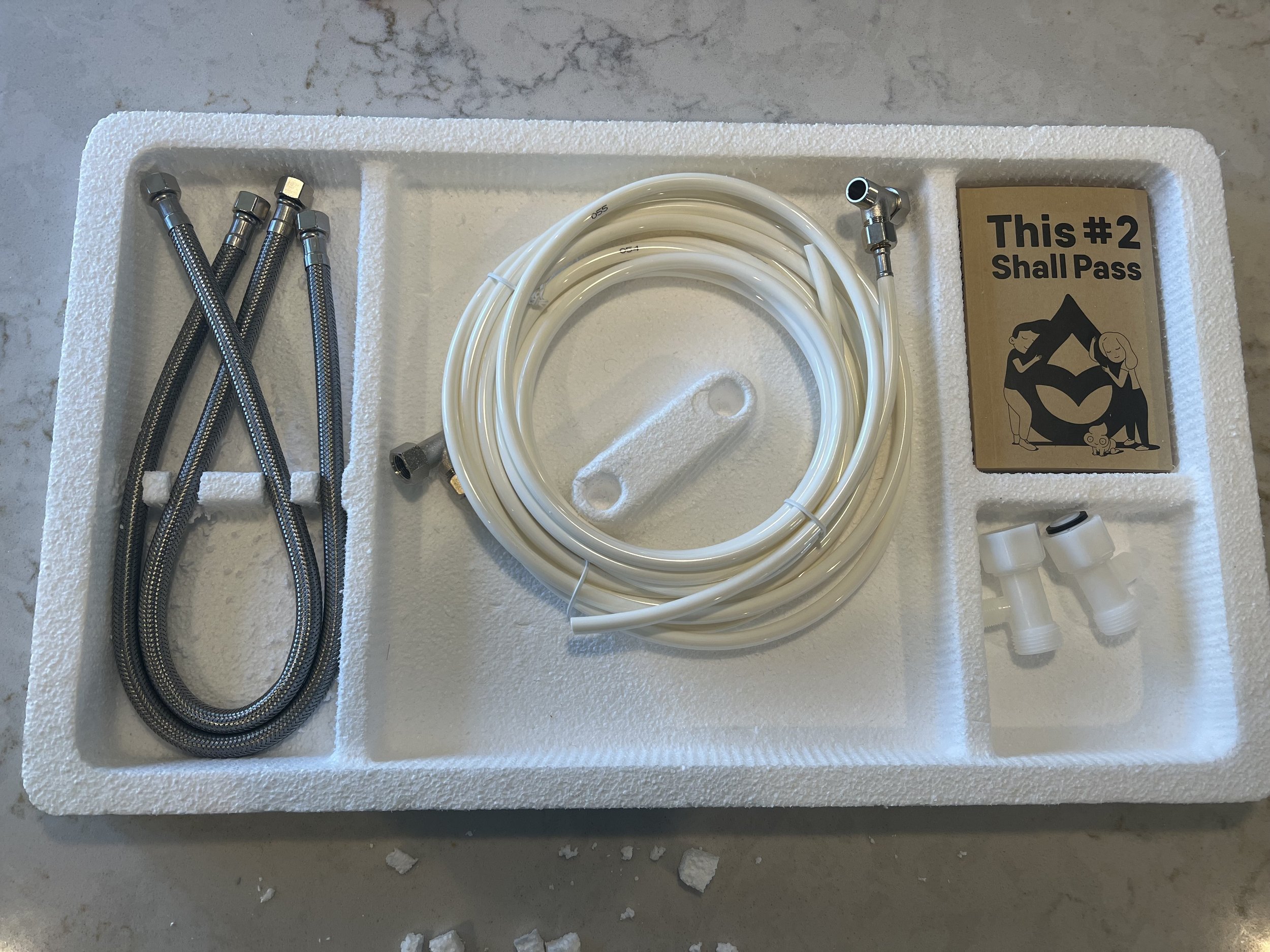

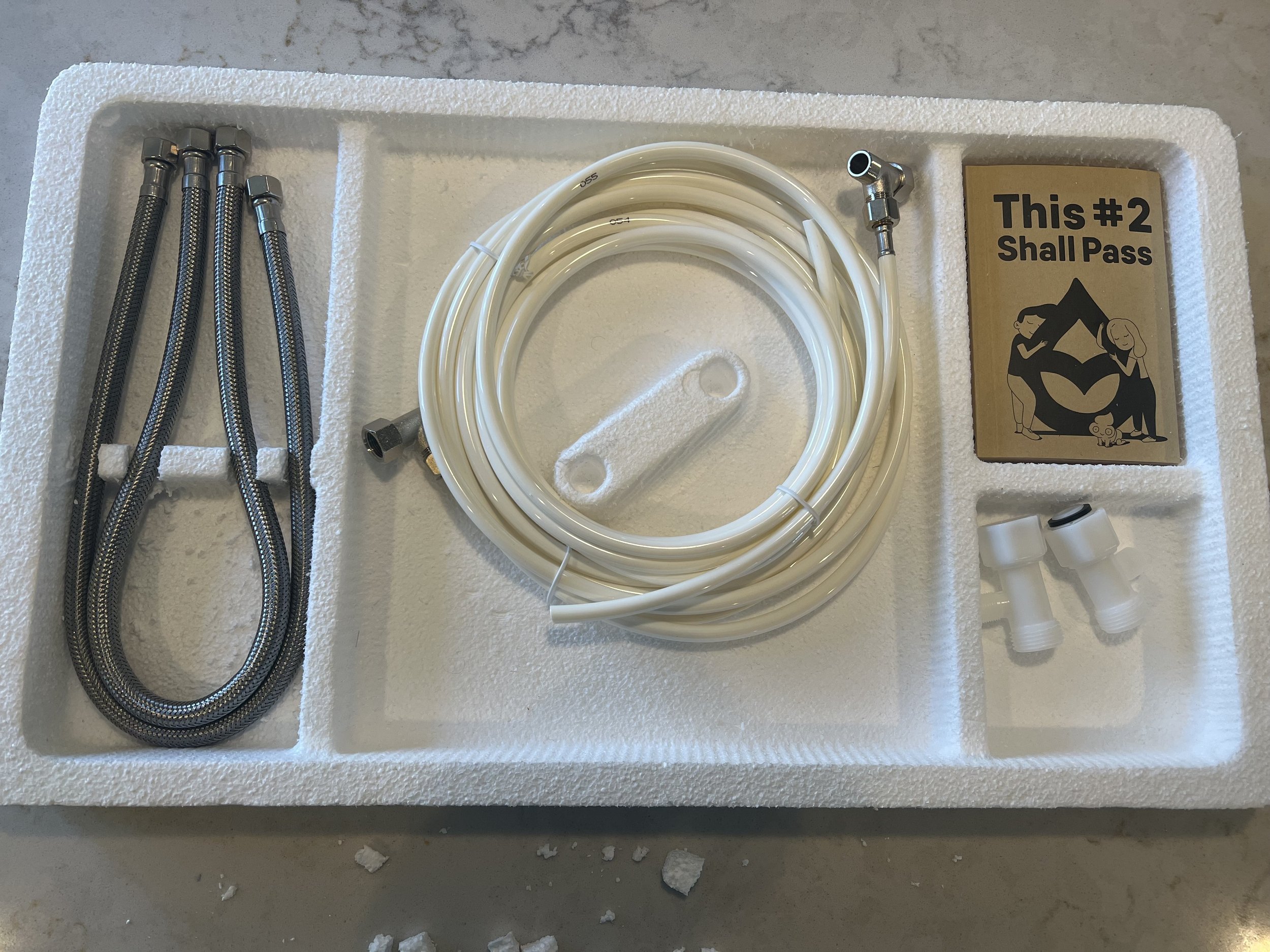

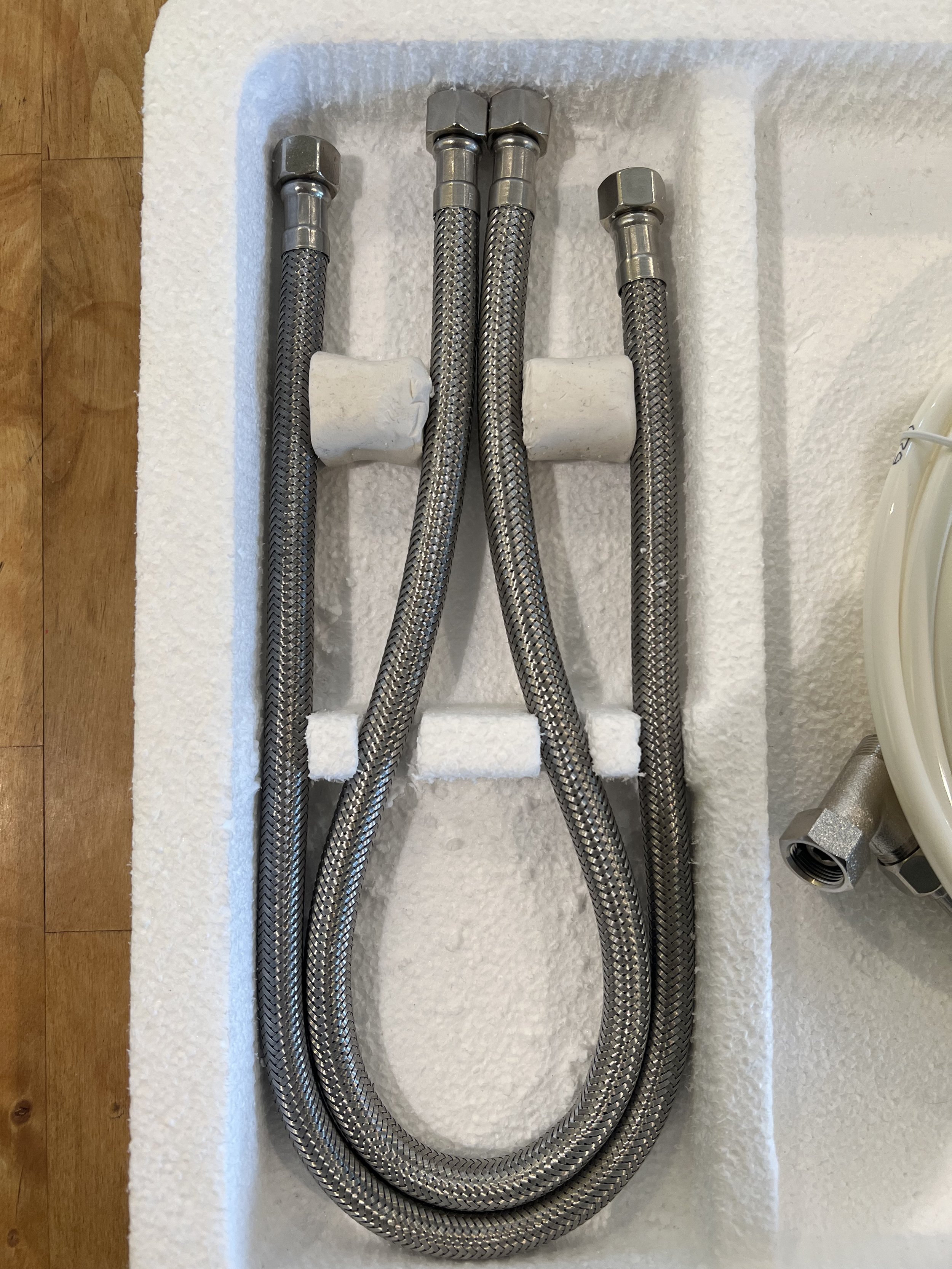

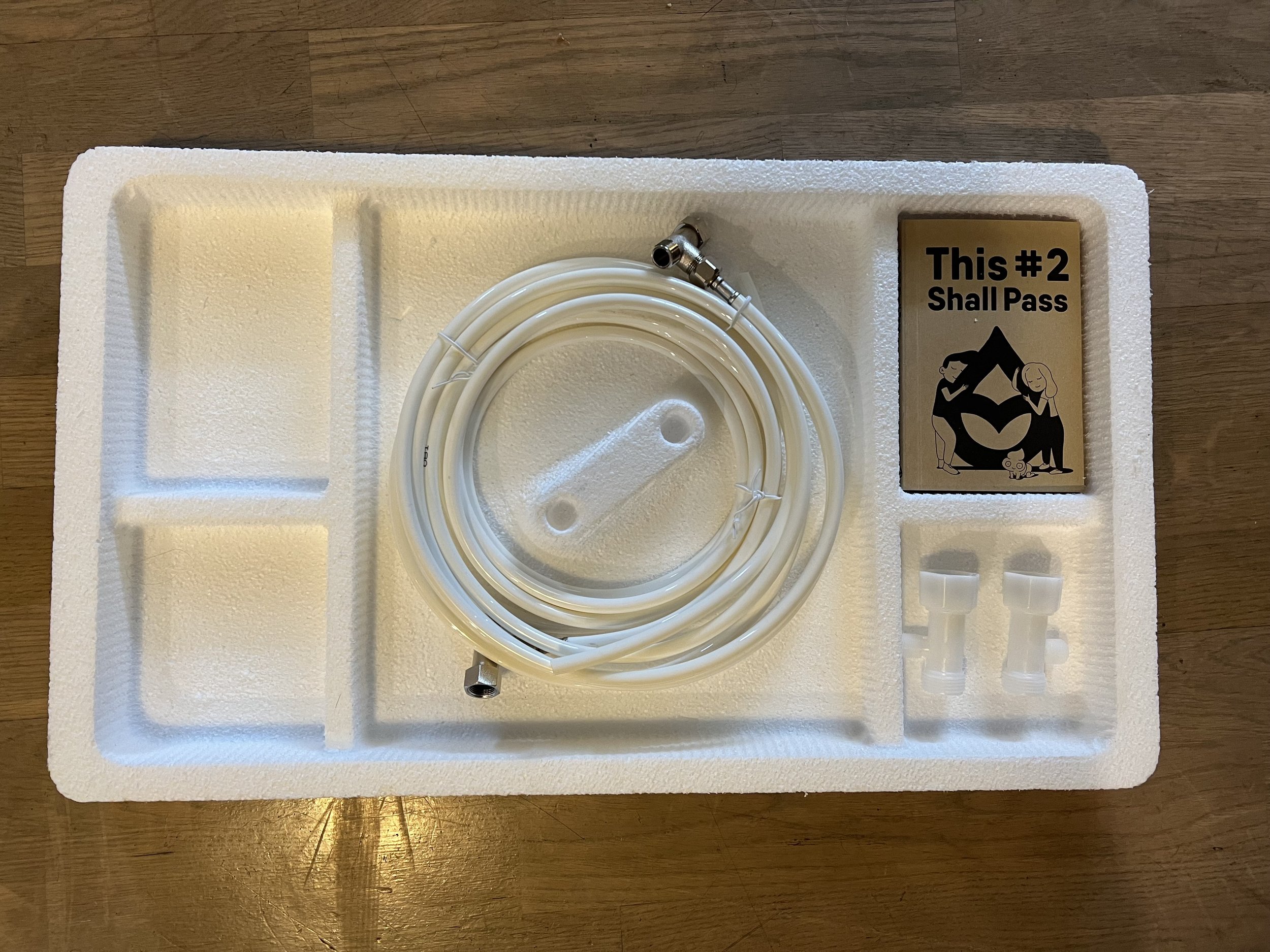

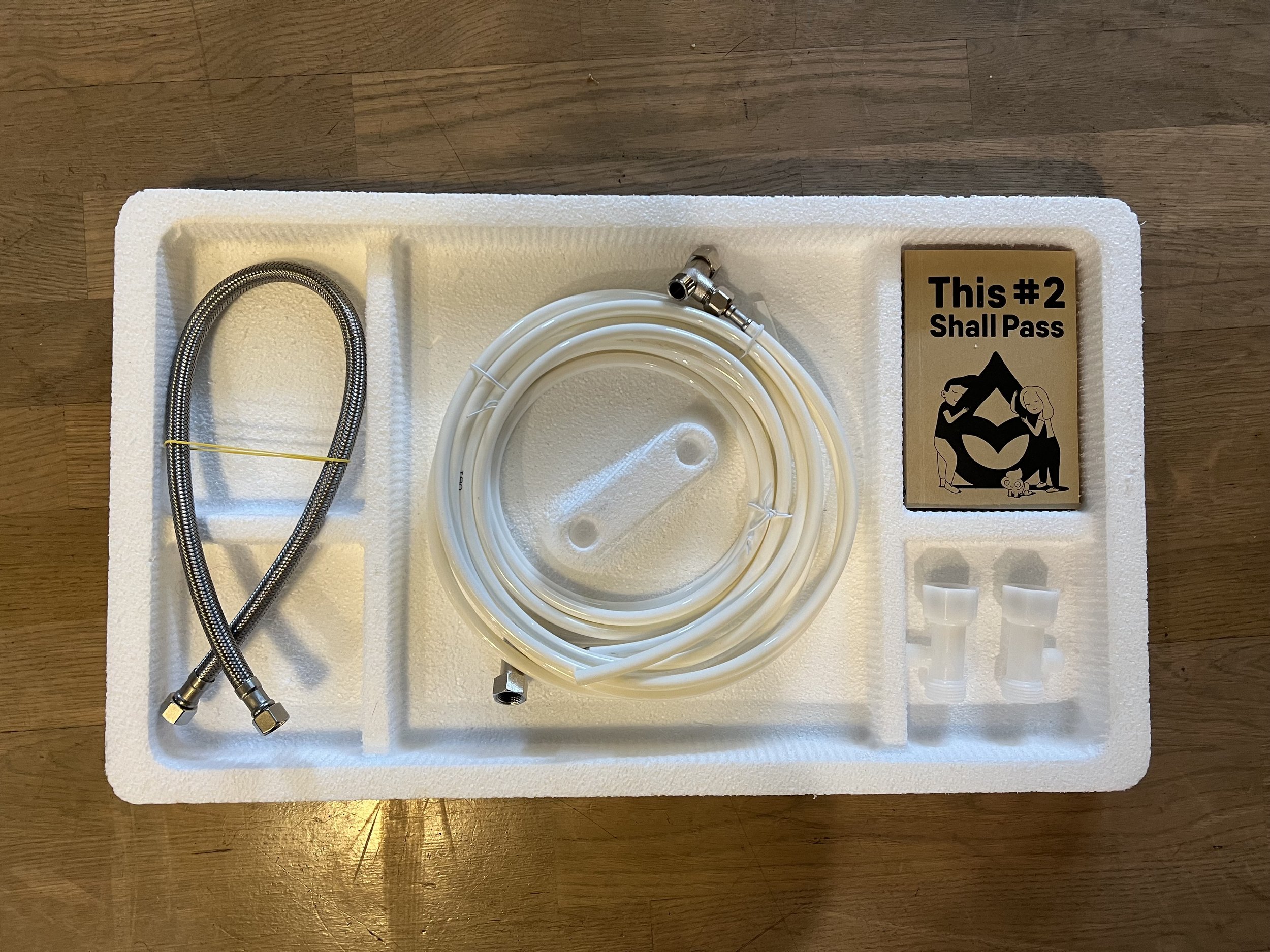

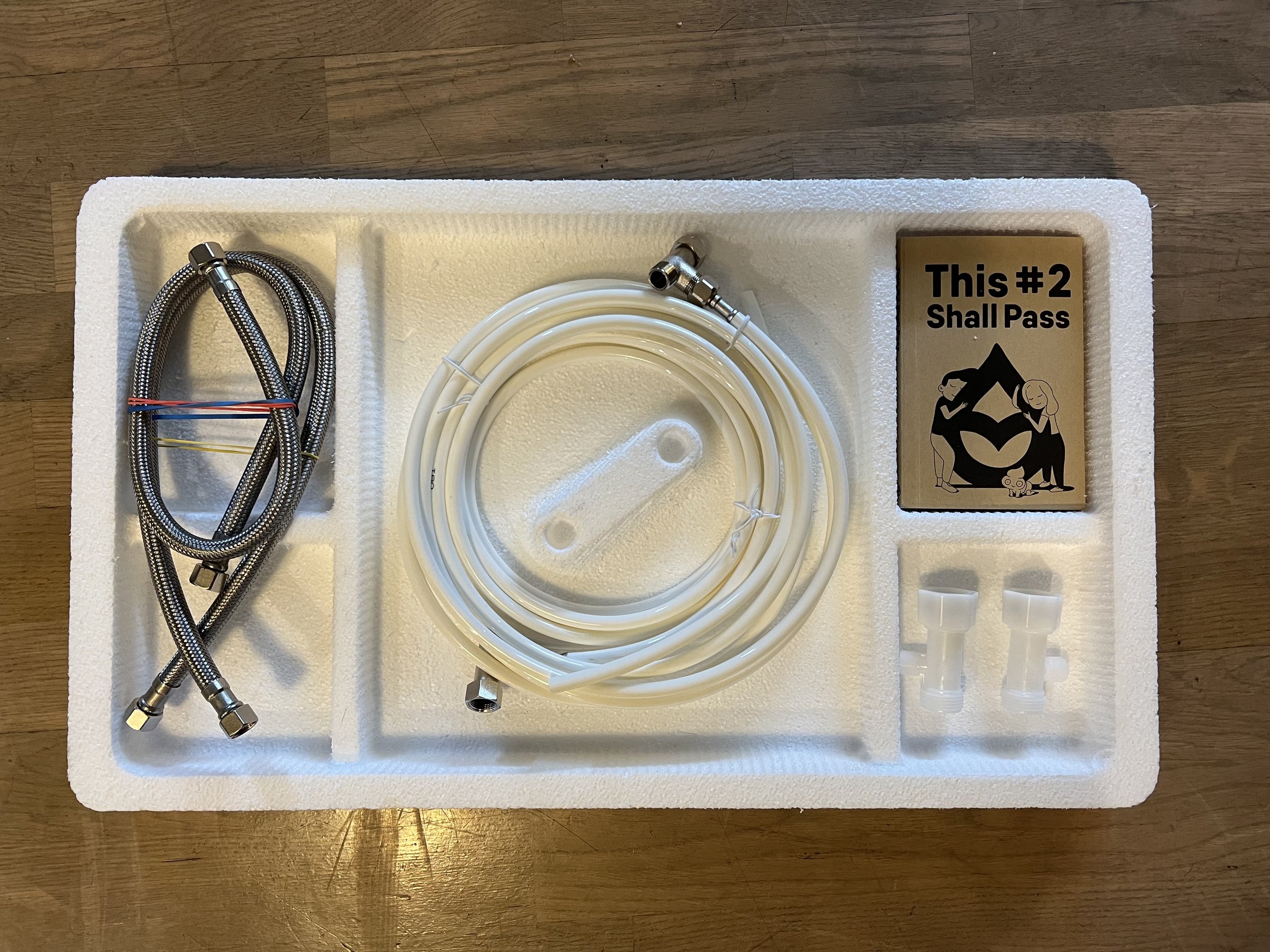

Foam Prototyping

Due to time and print-bed size restrictions, I elected to use CNC machined foam over 3D printing to validate the design. At a cheap cost, this allowed the fit and layout of the components to be physically verified. The foam prototypes directed the decision to make some final tweaks such as expanding the central boss to a circular geometry, implementing ingresses to allow for easier pickup of components, and flipping component cavities.

Tooling and Production

After being confident in the design, tooling was created and subsequent samples were inspected. The T0 sample was near perfect with the exception of the quality of debossing and hole cutouts. After addressing these issues, pilot production went smoothly, and production was approved.