Hello Tushy

Position: Product Development Intern

Role: Packaging Design, Material Research & Selection, Validation, Sourcing

Timeline: Apr 2021 - Jun 2021

Ace Packaging

I happened to join the Tushy team during the final development stages of their new premium product, The Ace. Although the product was already designed, the packaging was yet to be determined. I had the liberty of designing, lasercutting, and validating diecuts to achieve a cost-effective and sustainable configuration for the Ace’s packaging. The final design considerations were as follows:

Ease-of-manufacturing

Ease-of-assembly

Container packing efficiency

Sustainability

Low unit cost

User experience

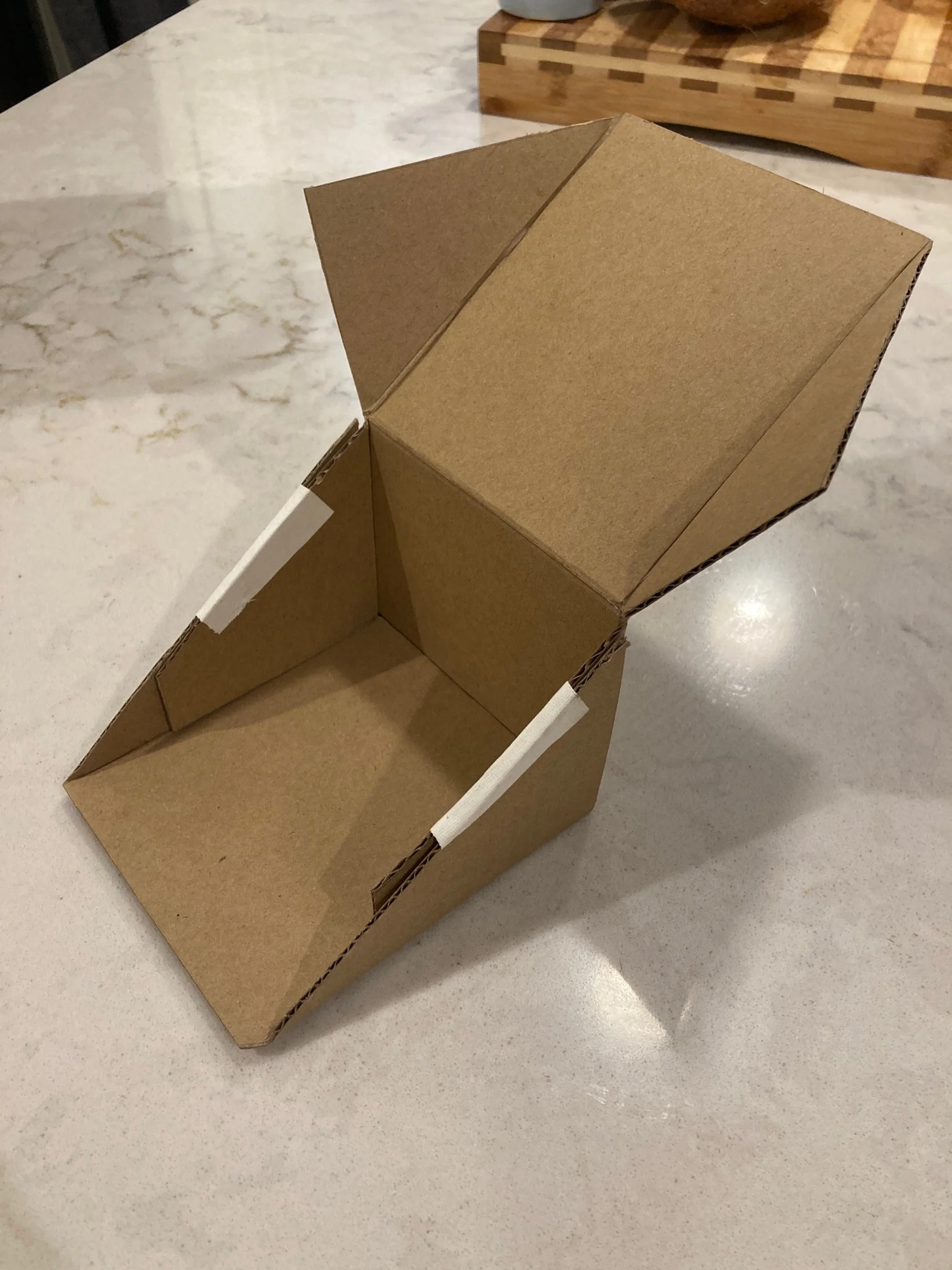

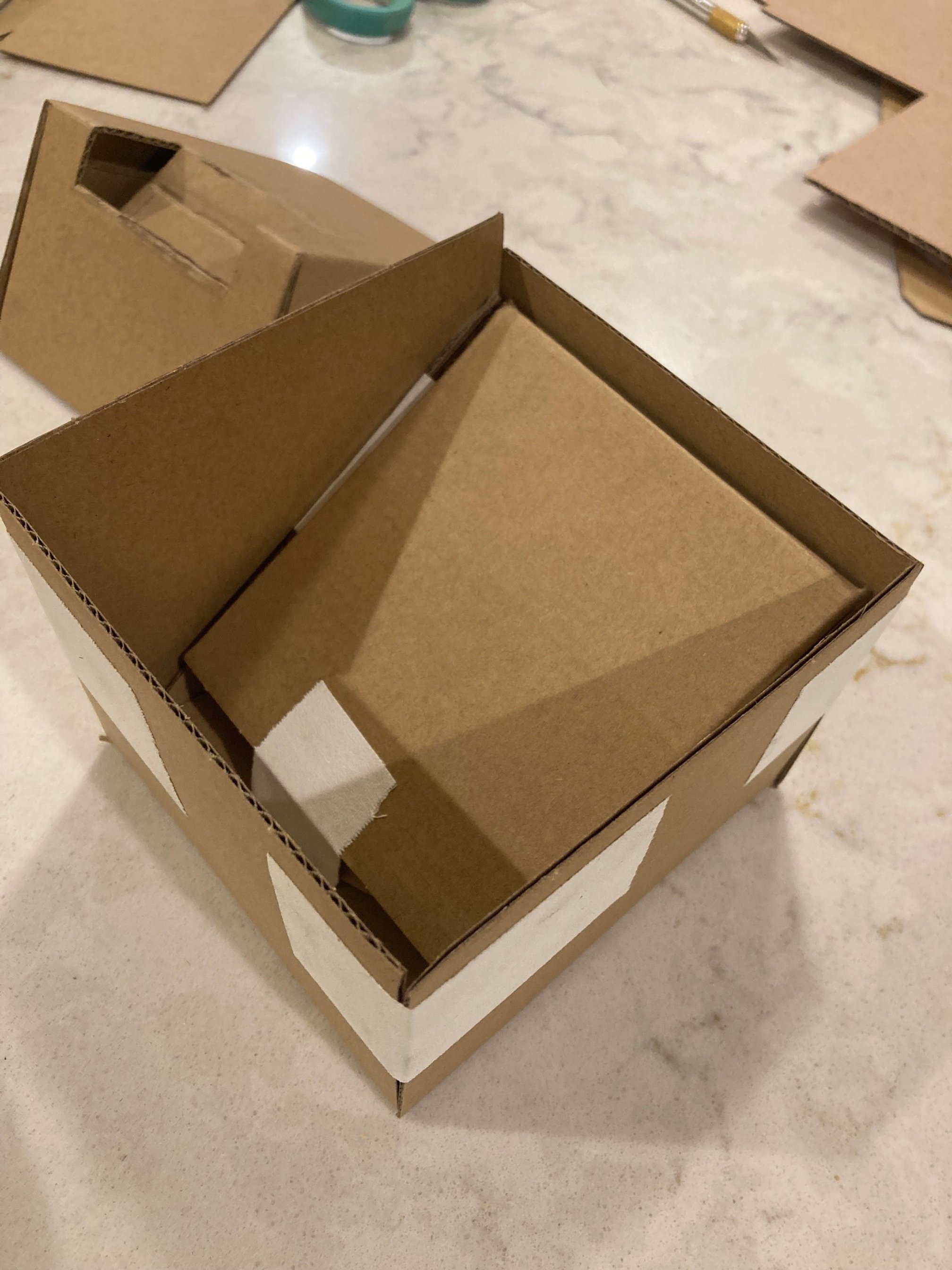

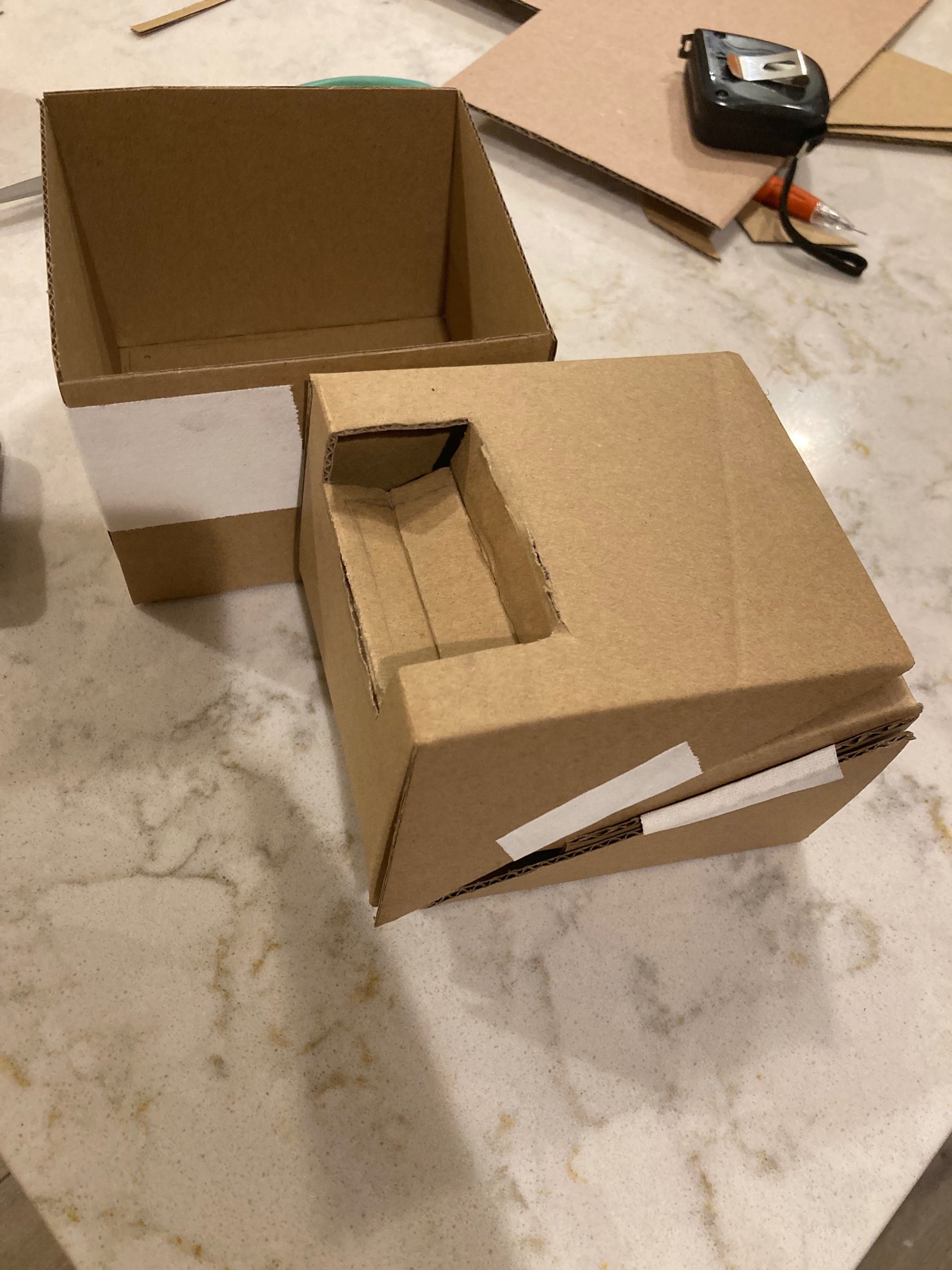

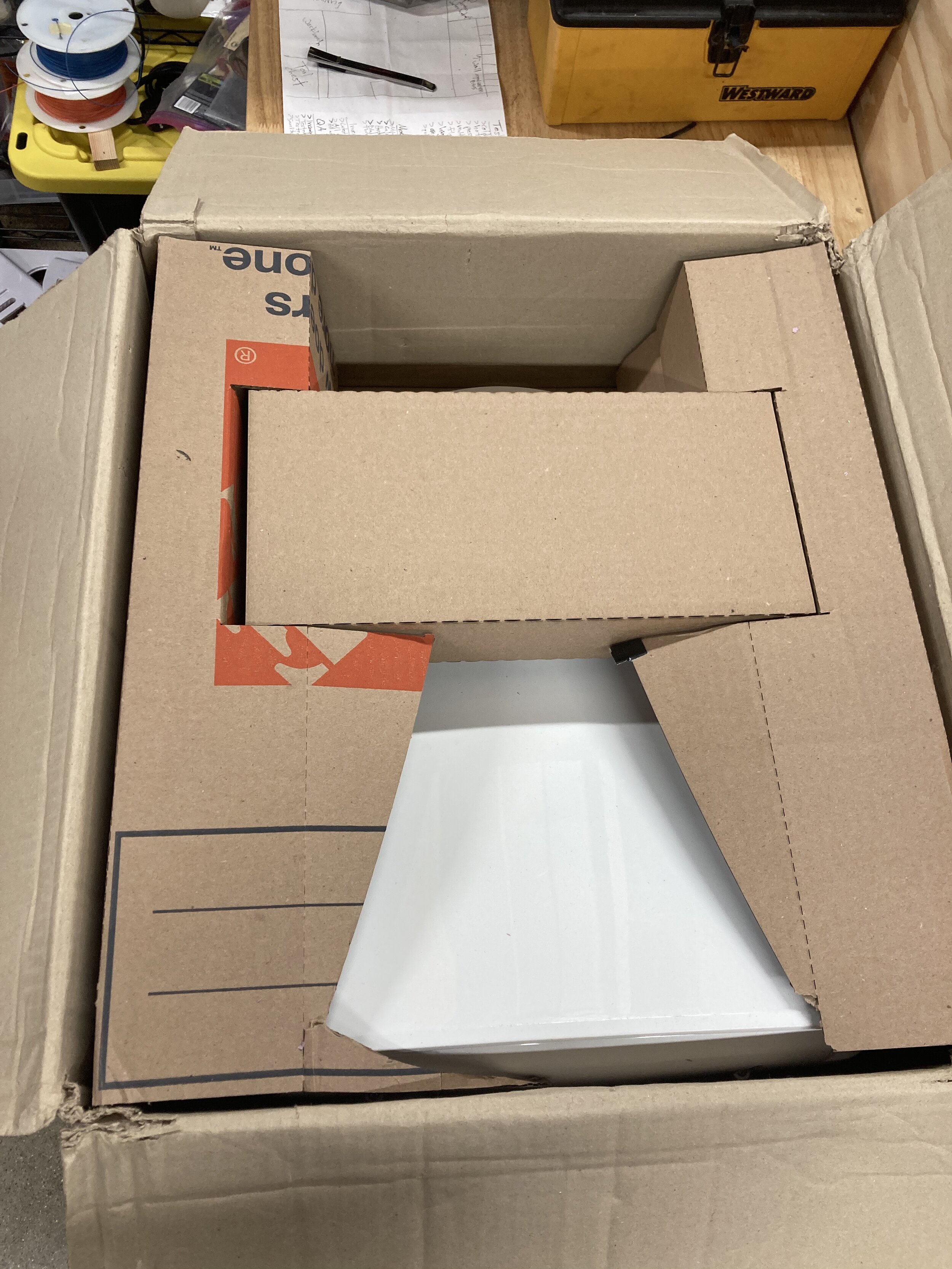

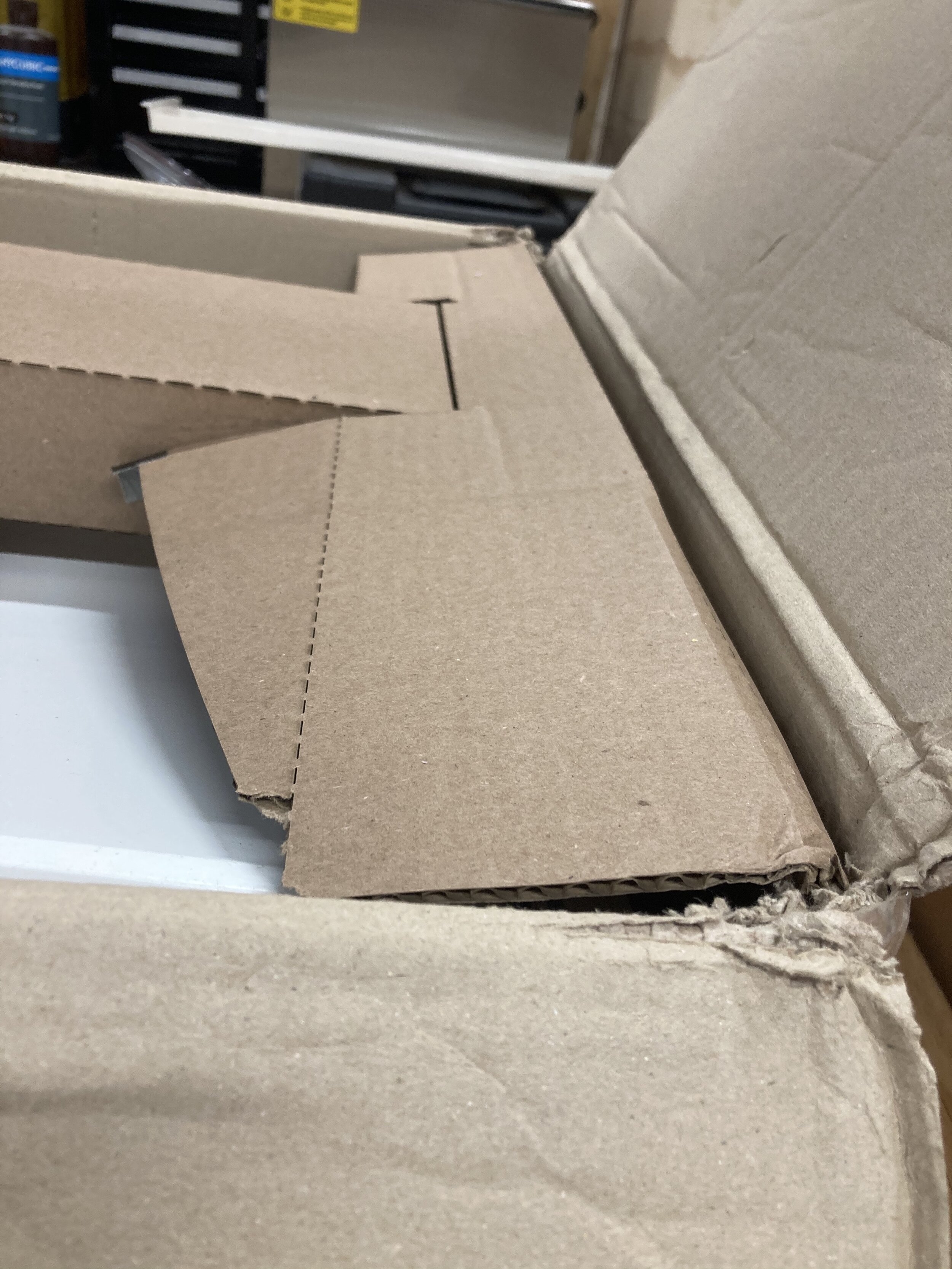

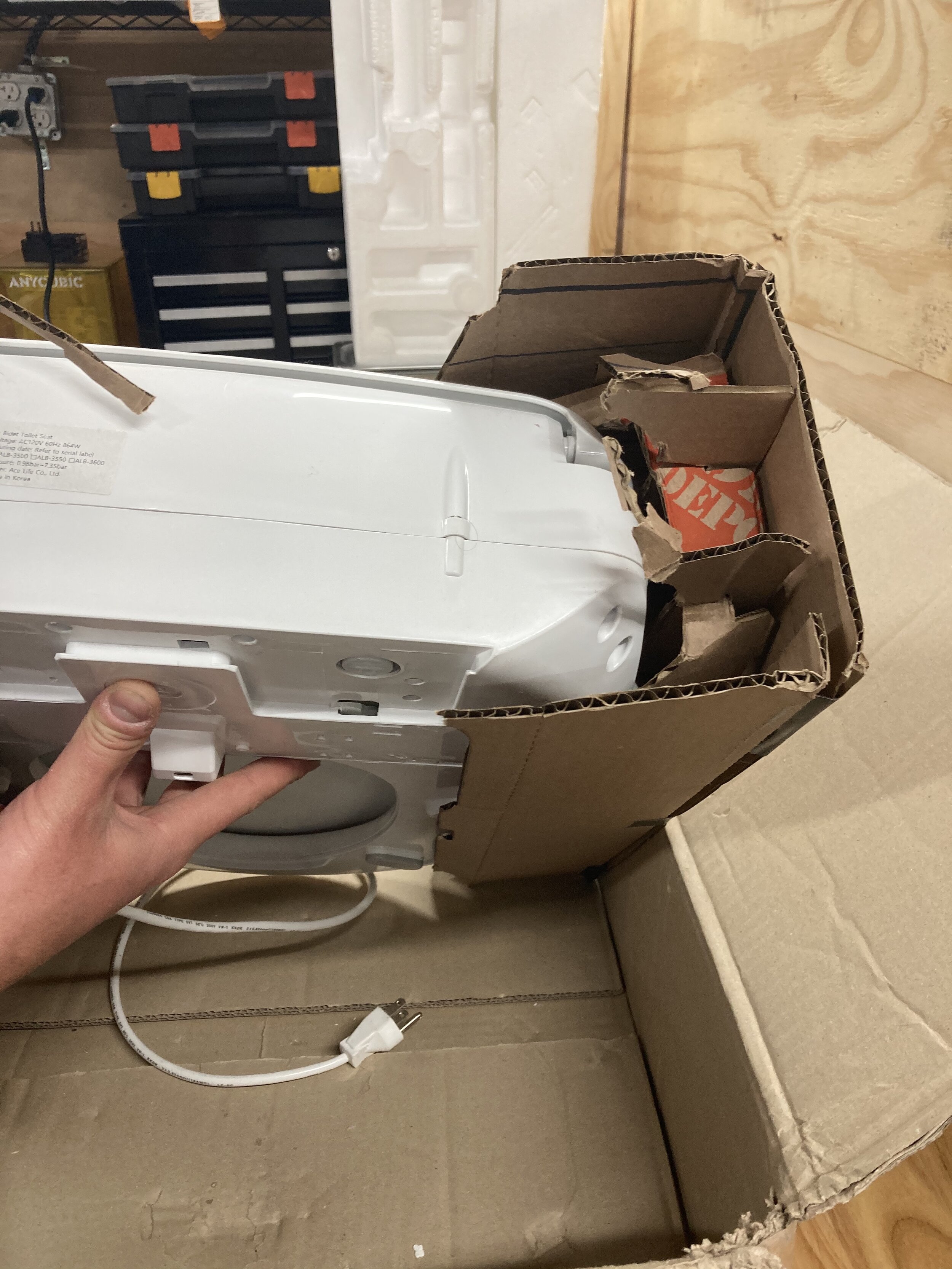

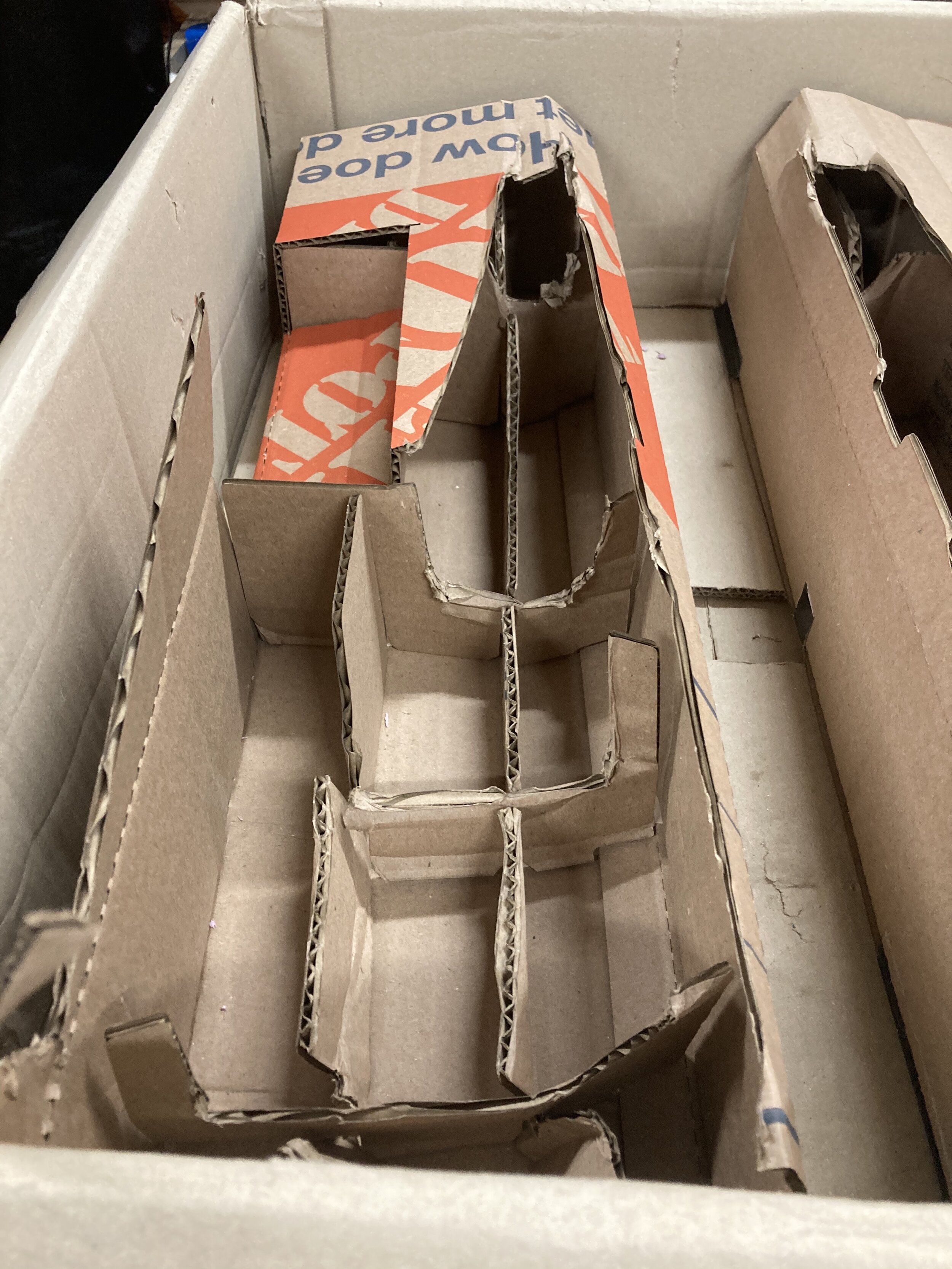

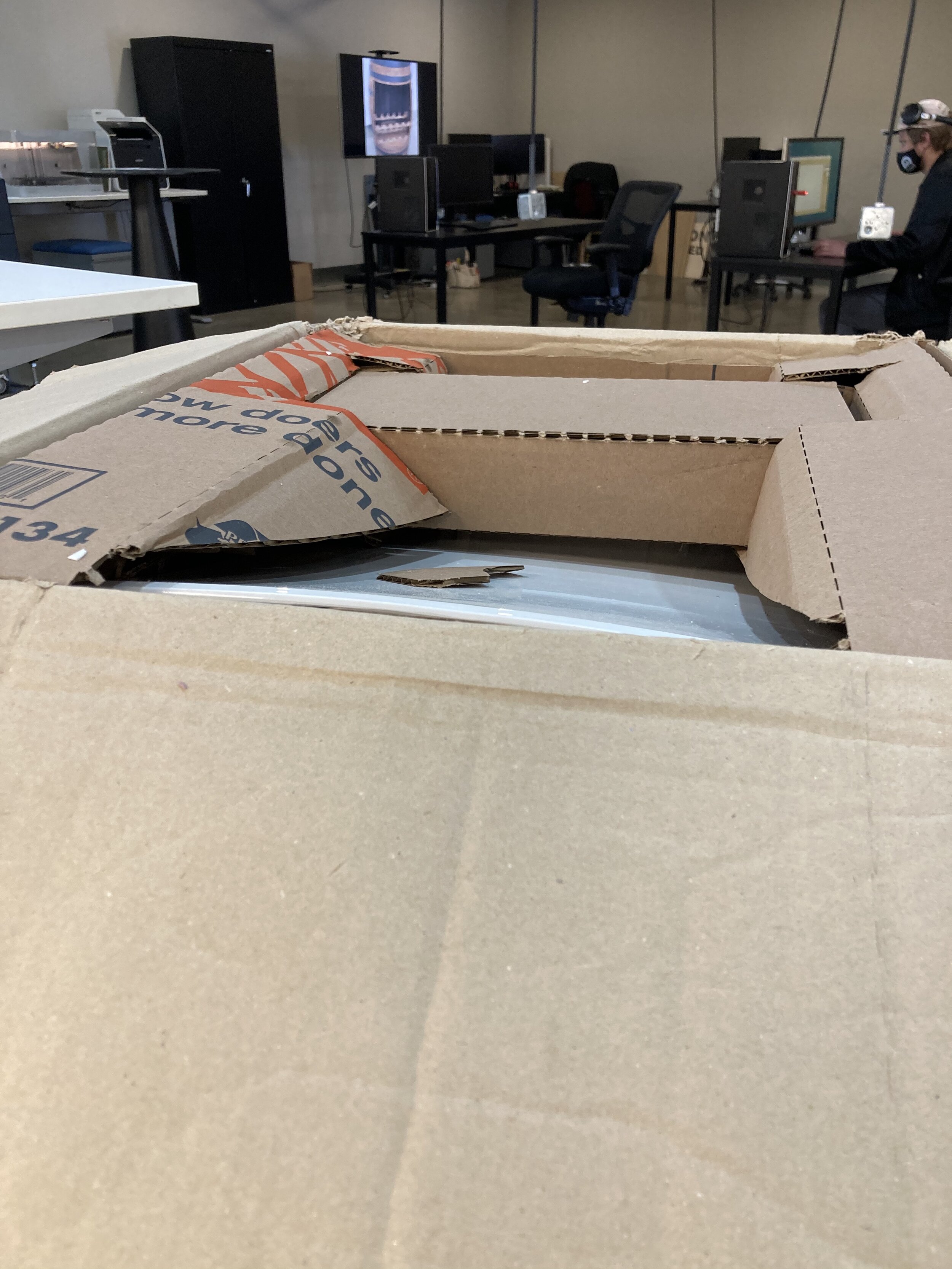

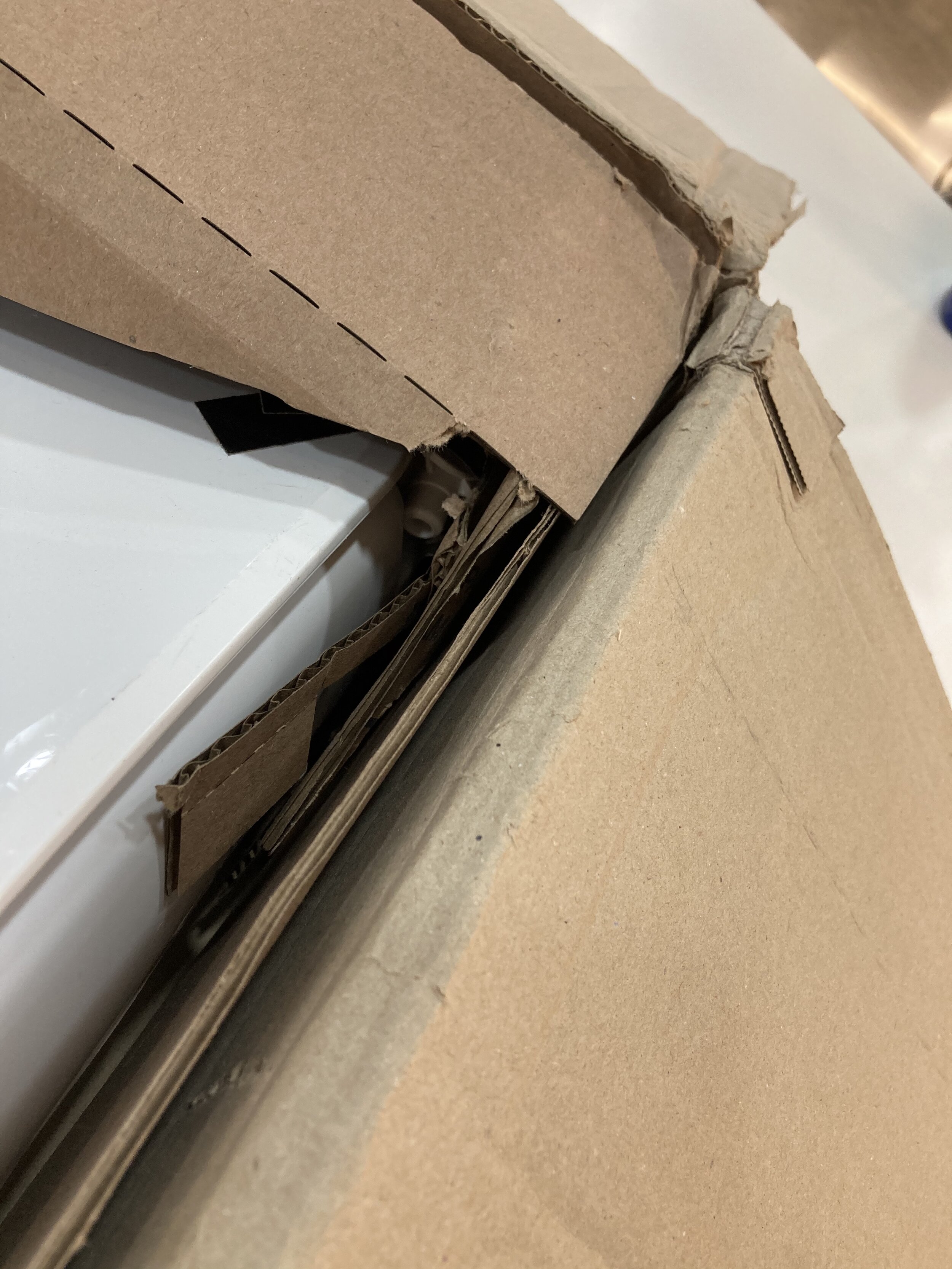

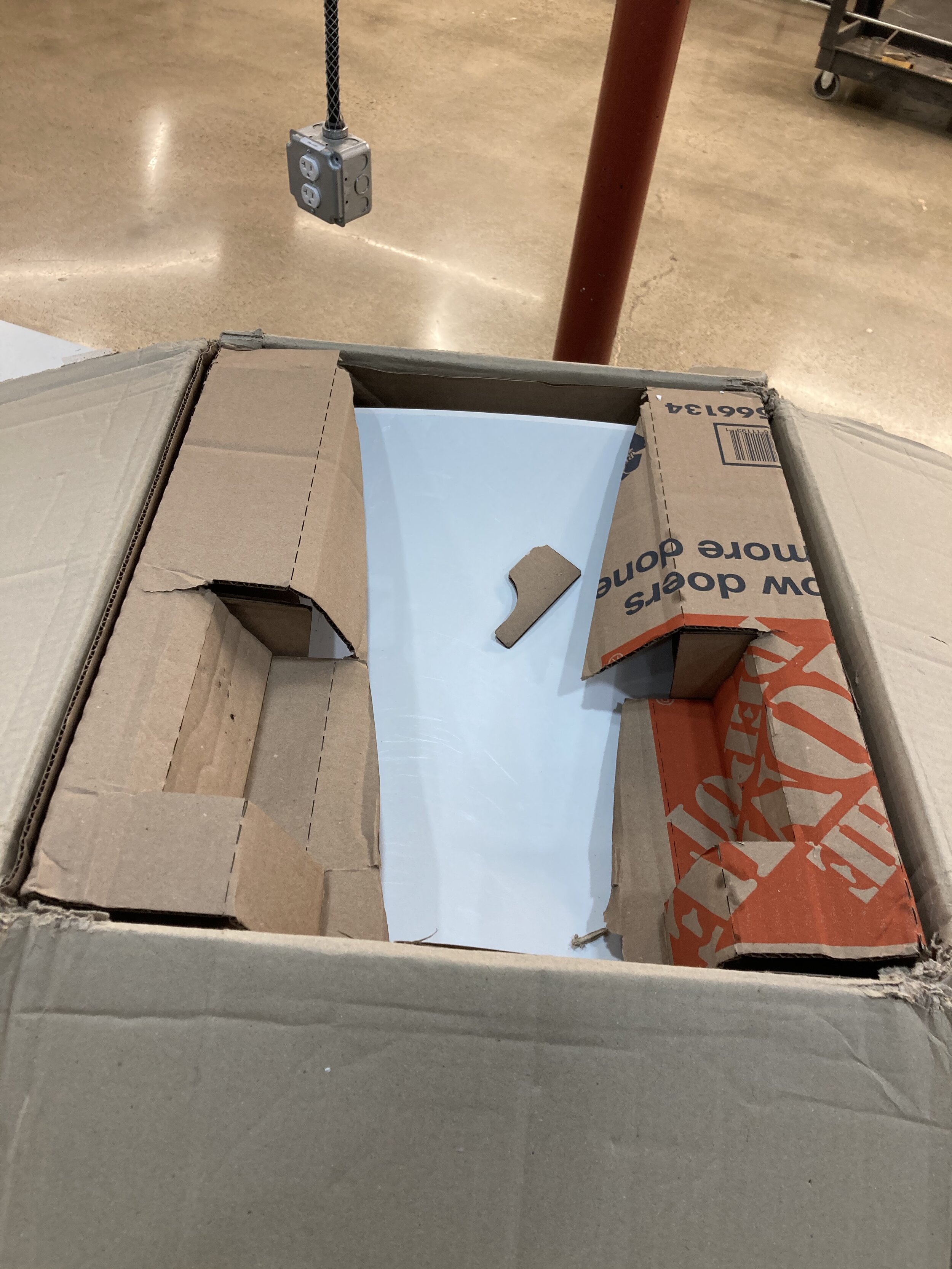

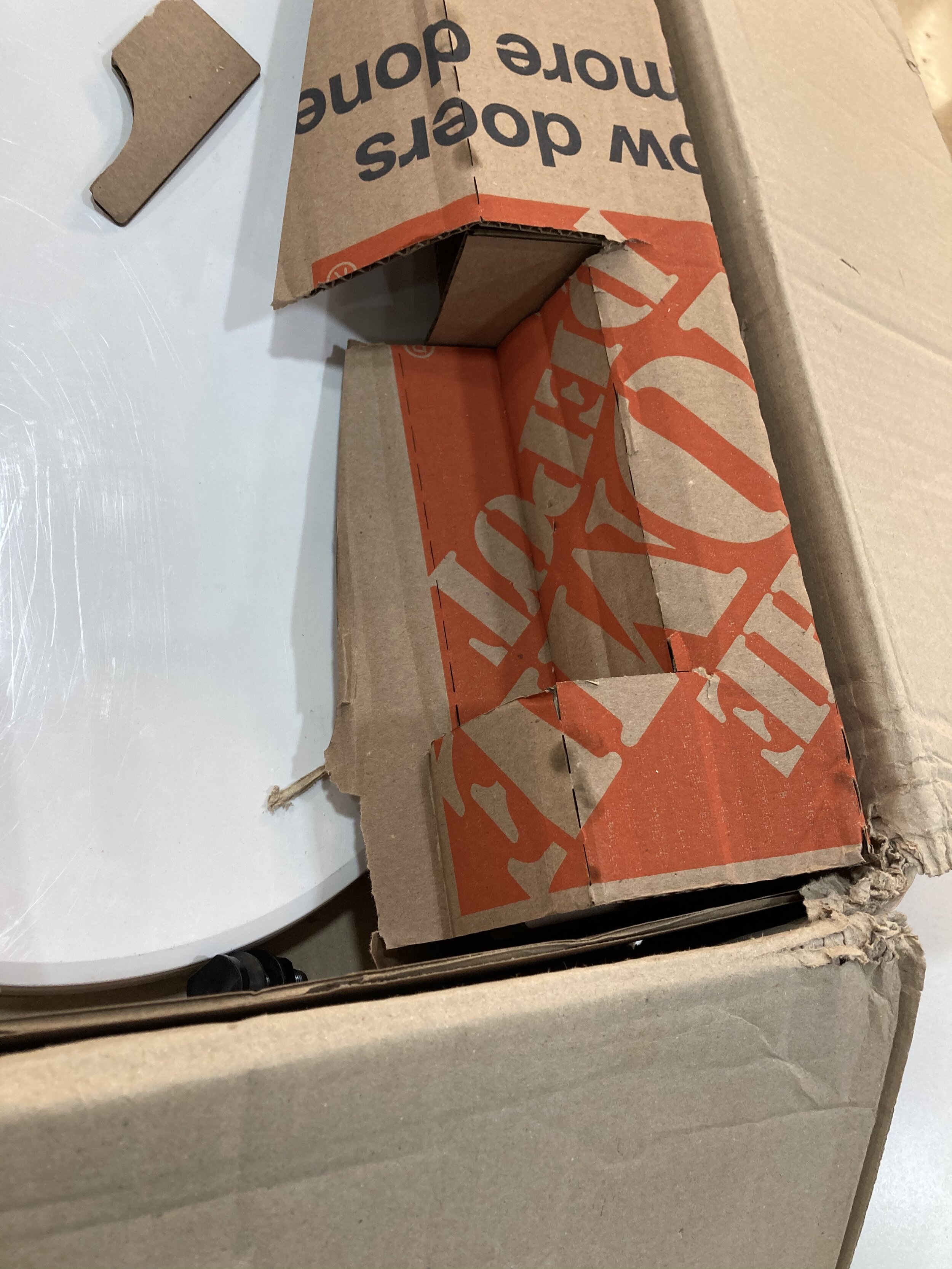

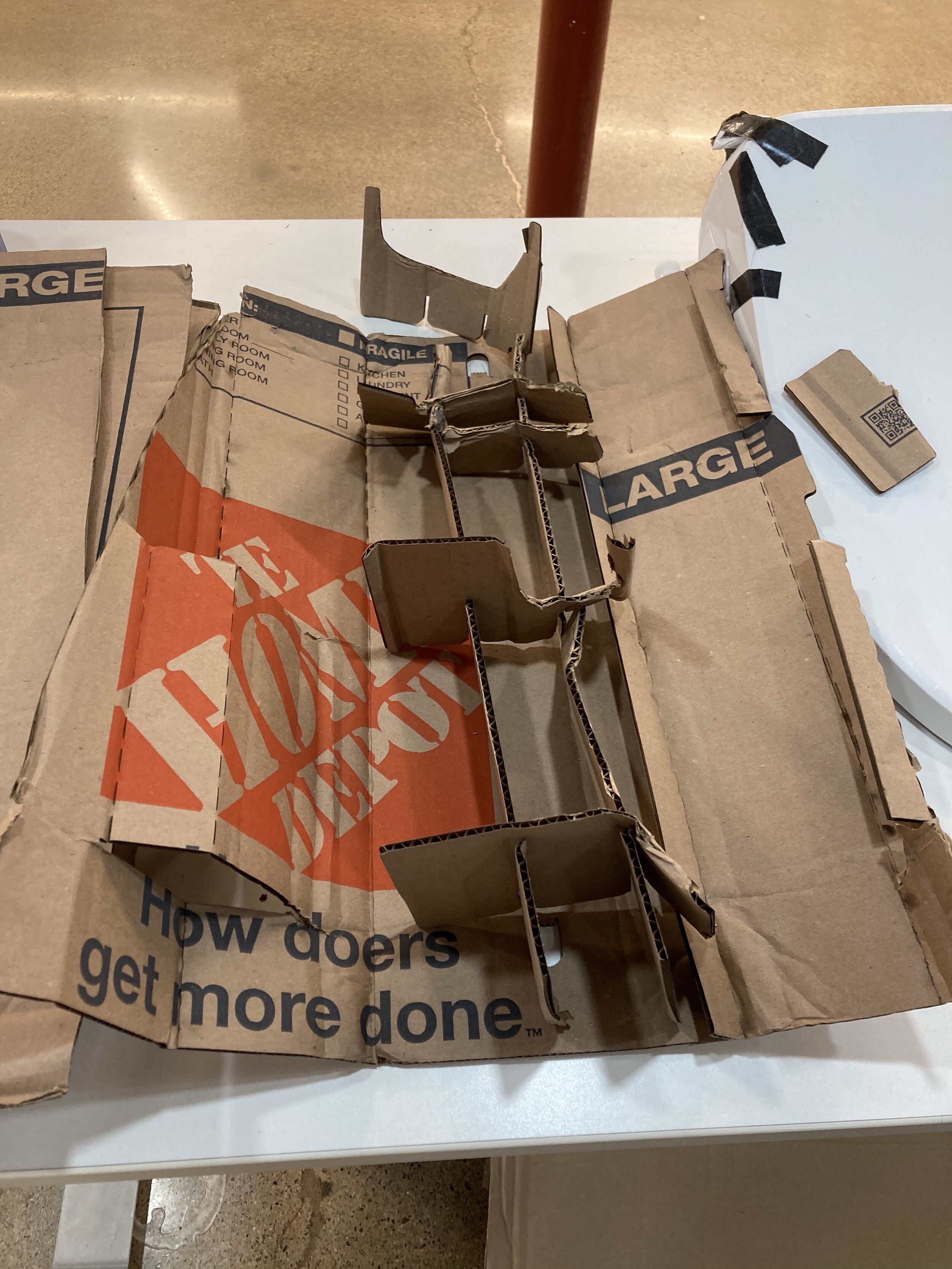

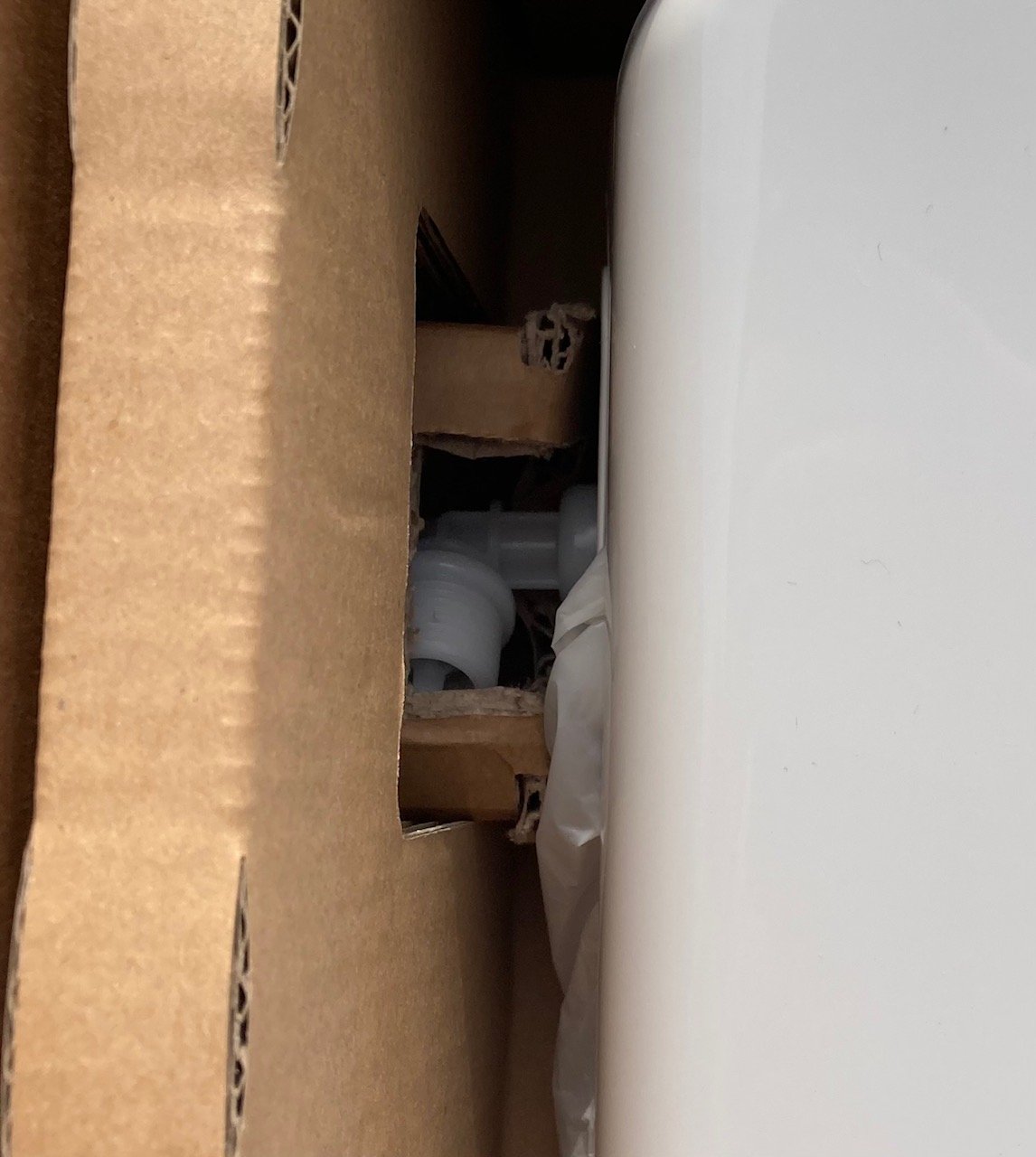

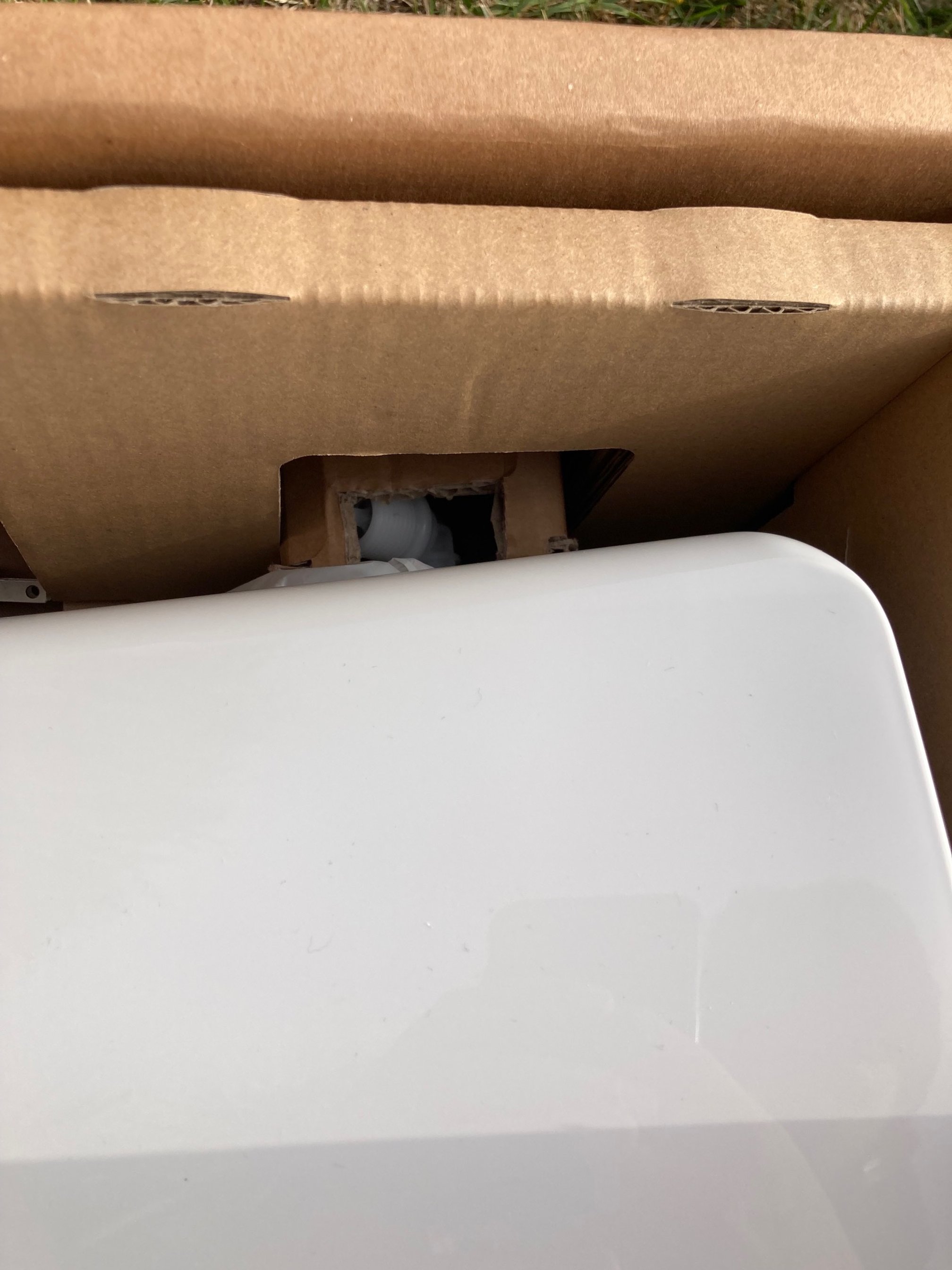

After onboarding, my first task with Ace packaging was to validate the existing packaging design through drop tests. A laser cutter was used to develop the prototypes and drop tests were performed and documented to industry standards. It was immediately apparent that the design had to go in a different direction, and to maintain our CM’s production timeline there was little room for error. Through observations made from these validation tests, the decision to consolidate the amount of parts was made.

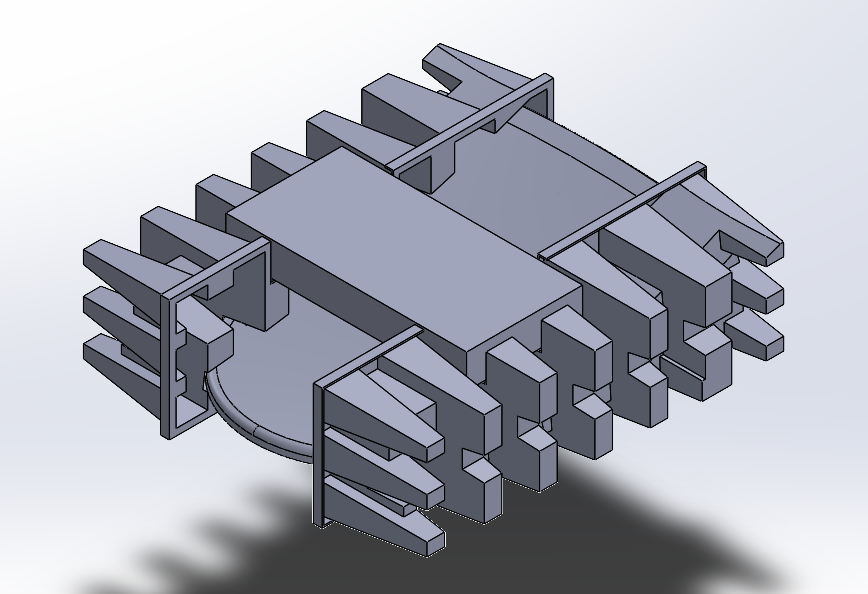

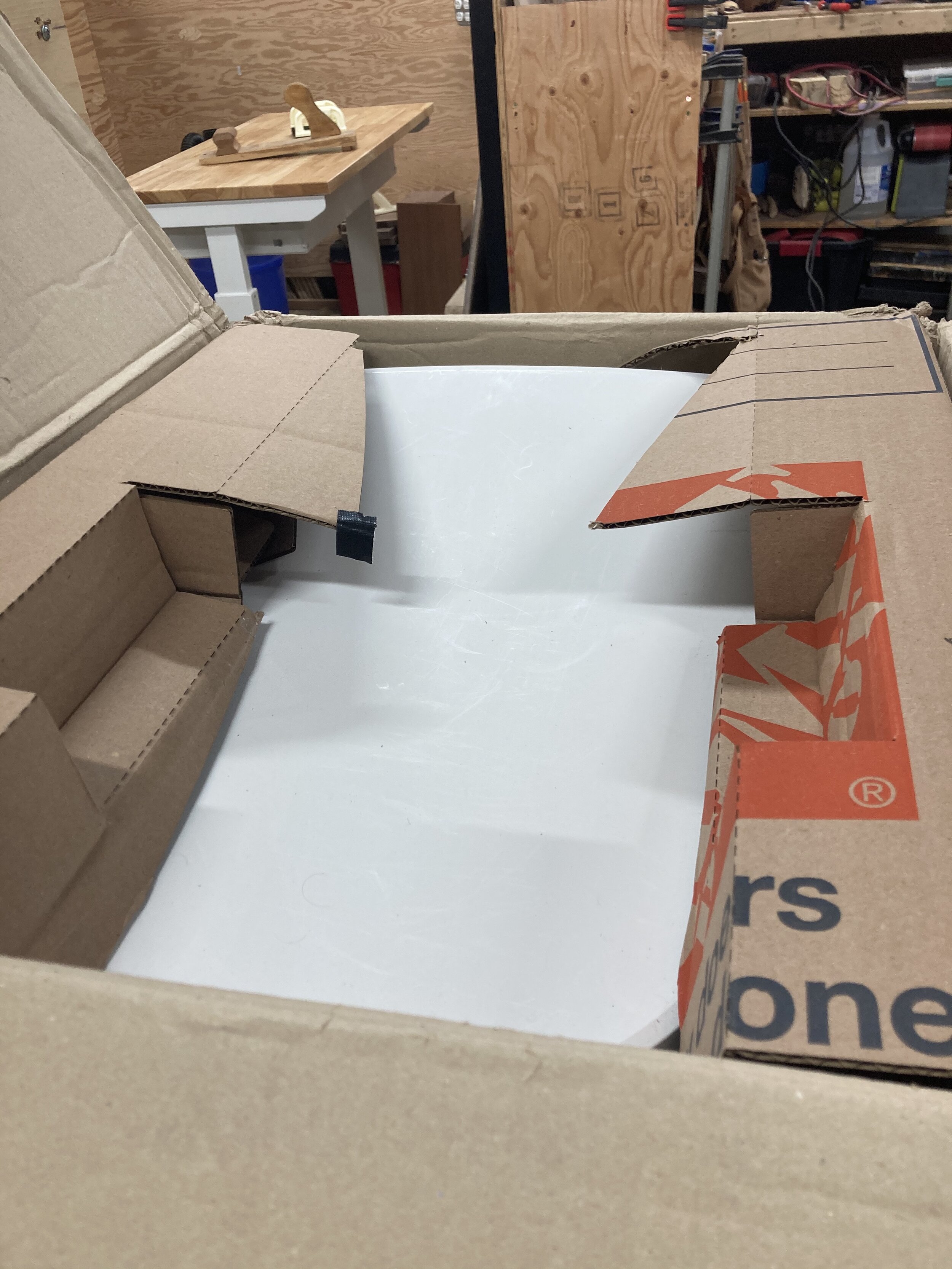

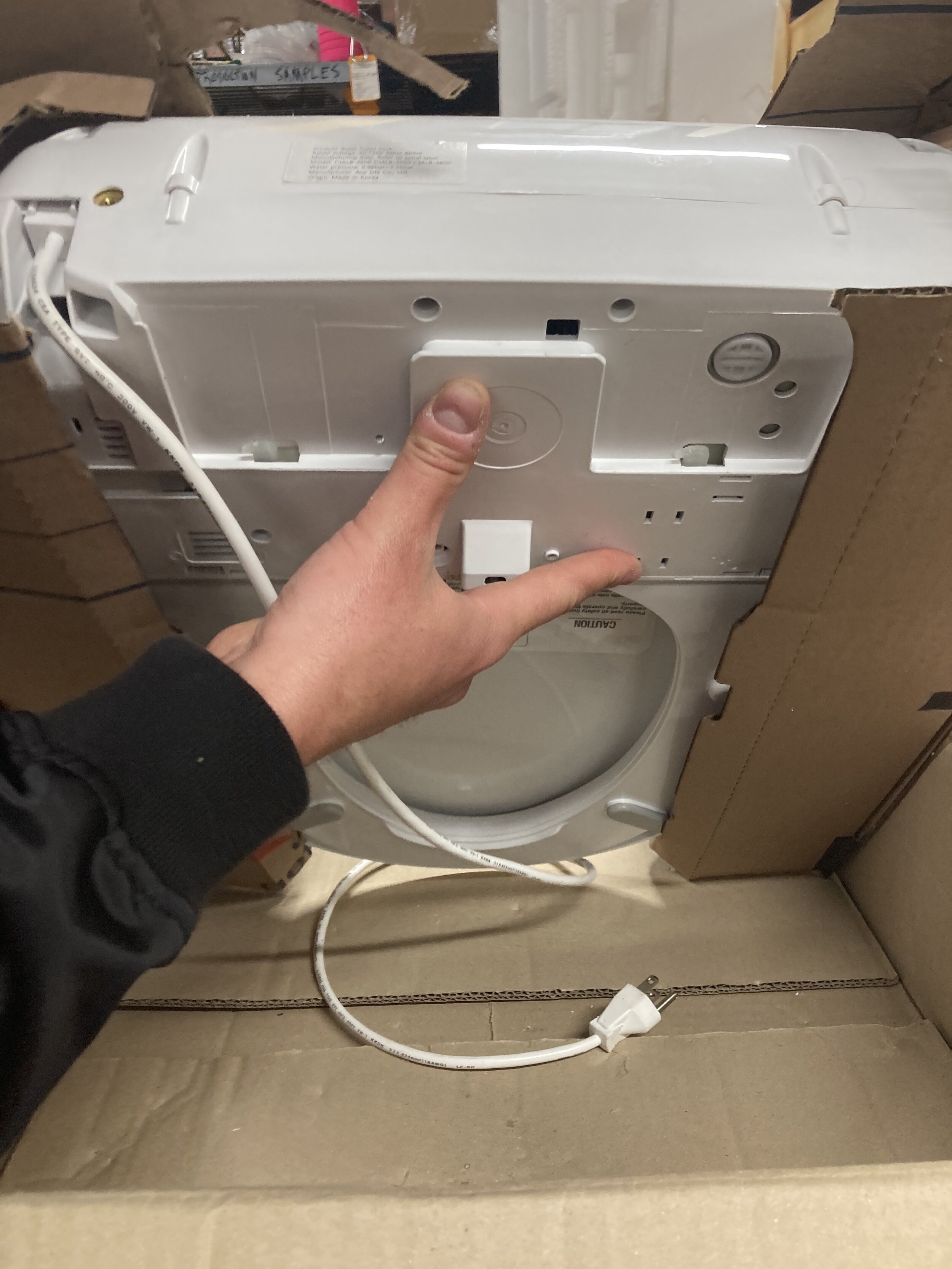

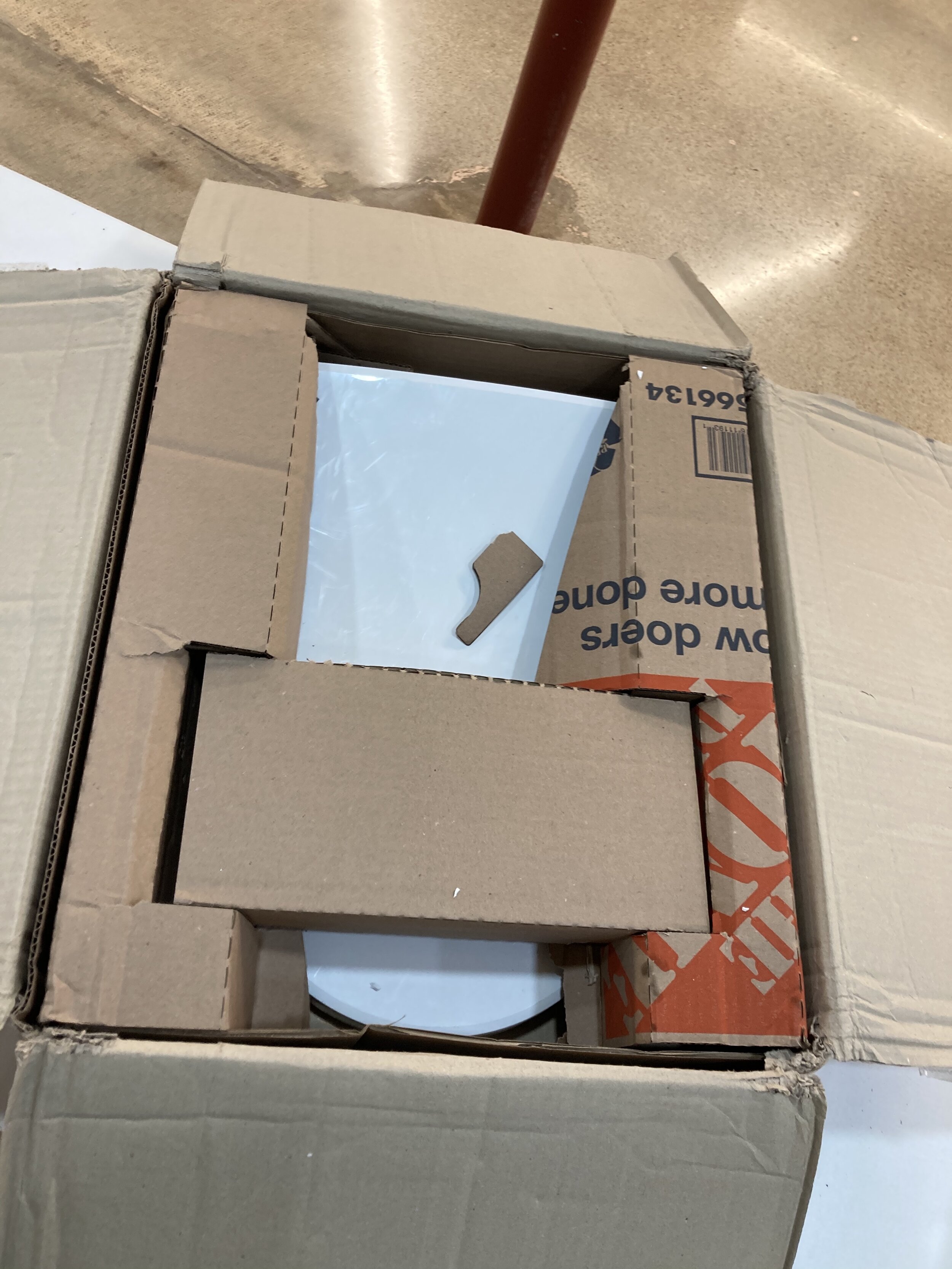

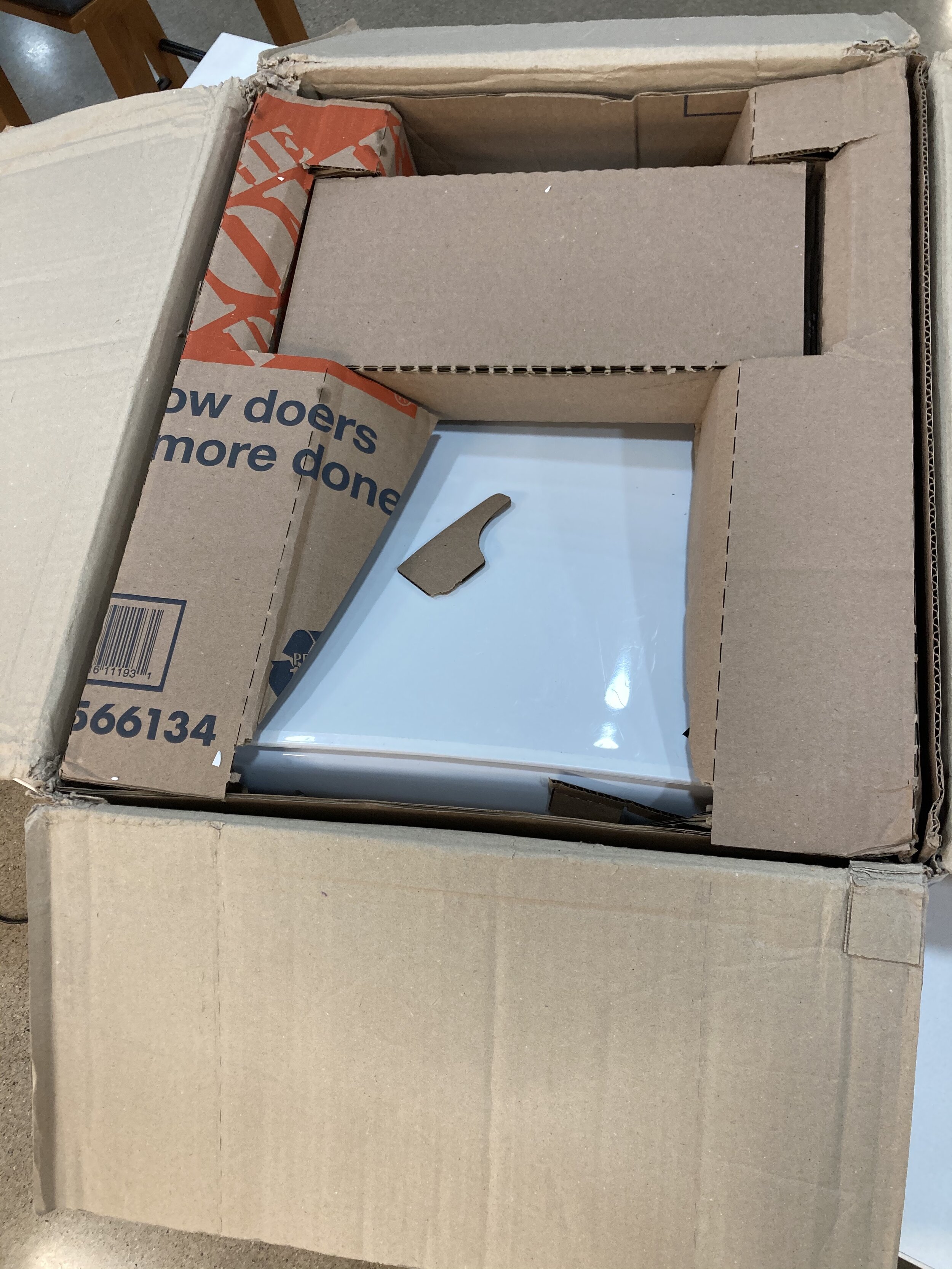

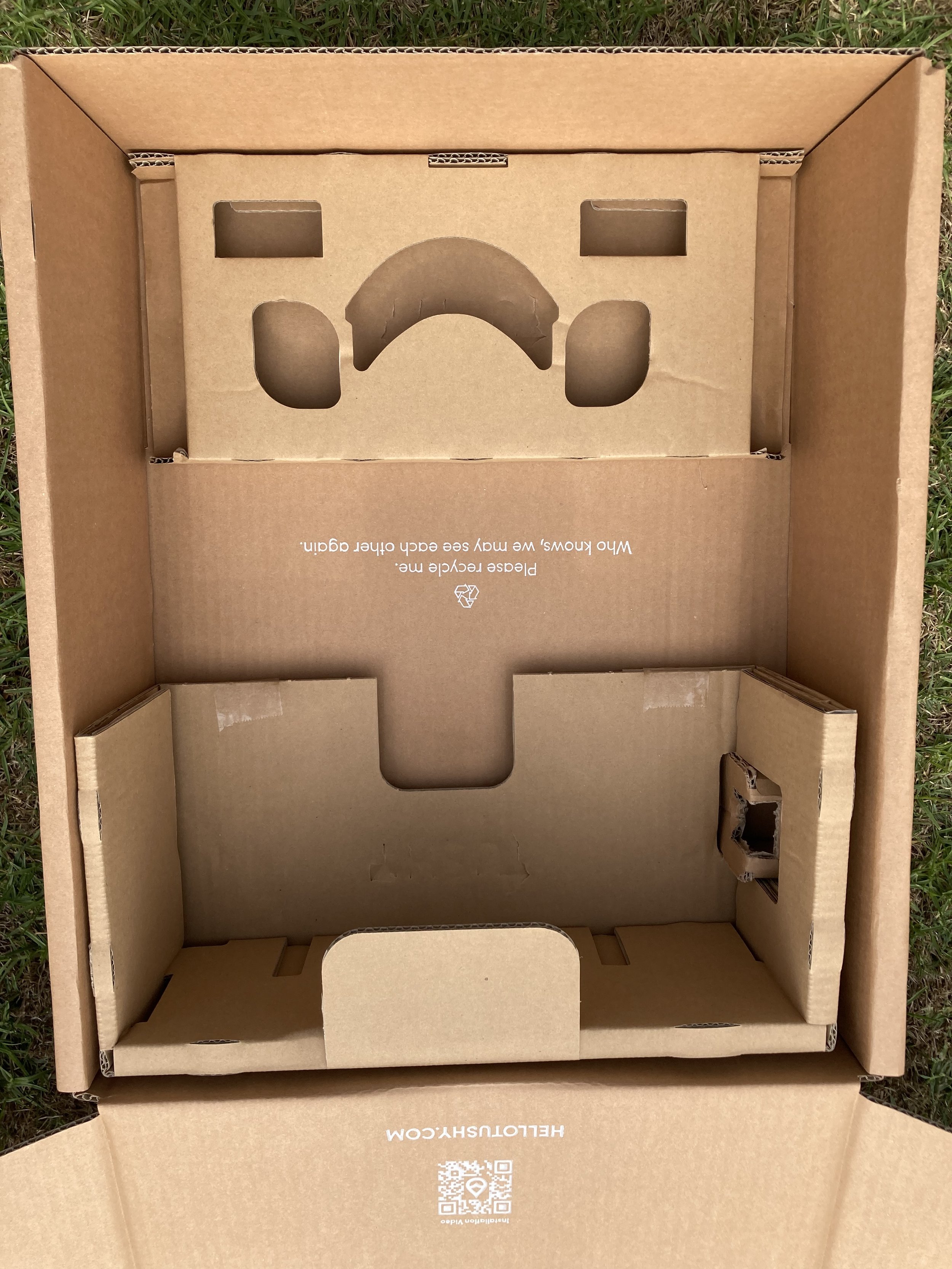

Back at the drawing board, we reconsidered our approach. The product was heavier in the back which required a sturdier support. Additionally, there are two versions of the Ace: round and elongated. It brings as many similarities to the packaging of these two products while maintaining adequate protection. Using the respective dimensions, the packaging was redesigned to use four diecut corrugate bodies: the rearpad, nosepad, nosecap, and accessories box.

This configuration was able to meet all of our design specifications after executing and validating 10+ iterations.

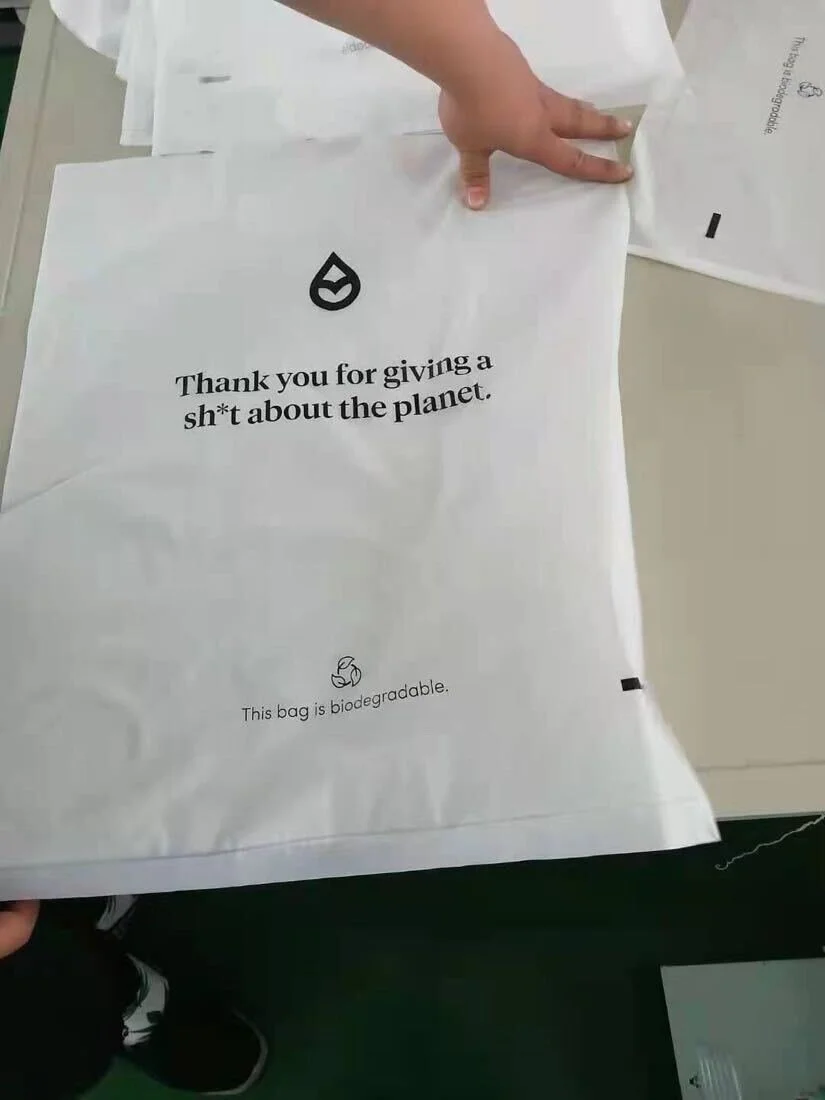

Once the final iteration was validated and approved, the bones of the packaging were settled. Next, we had to prevent cosmetic damages to the product. A key insight from the drop tests was the scratch-prone polypropylene material. During movement, deflections cause the cardboard to rub against the lid of the bidet. I was tasked with identifying and implementing a solution. This process began by exploring eco-friendly materials. At Tushy, we are encouraged to be creative and I wanted to take full advantage of this privelege. With that said, my initial idea of using banana leaves was put to a stop after performing physical testing. The leaves were sustainable, beautiful, and cost effective, however once dried they failed to provide adequate protection. My next material research venture led me to stationary stores, identifying any material that can draw inspiration. I came across Unryu paper which is an elegant variation of rice paper. Although this was a great candidate, it was difficult to find a supplier that met our budget. As time dwindled, I took to more conventional solutions: bags. Bags are fantastic, humans have been using them for ages, however the difficulty is the prominence of plastics in their production. A trip to the grocery store quickly calmed that concern as the biodegradable produce bags caught our attention. I began my research on bioplastics, determining shelf life, production, and lifecycle process, and found multiple overseas vendors for these products. After submitting the design specifications, I compared my respective negotiations and arrived at a trustworthy and cost-effective supplier. The final selection was a 22” x 18”, 40 Mic, compostable corn starch bag with one color printing on one side. I coordinated samples and once approved, organized the payment terms and timeline with the supplier.

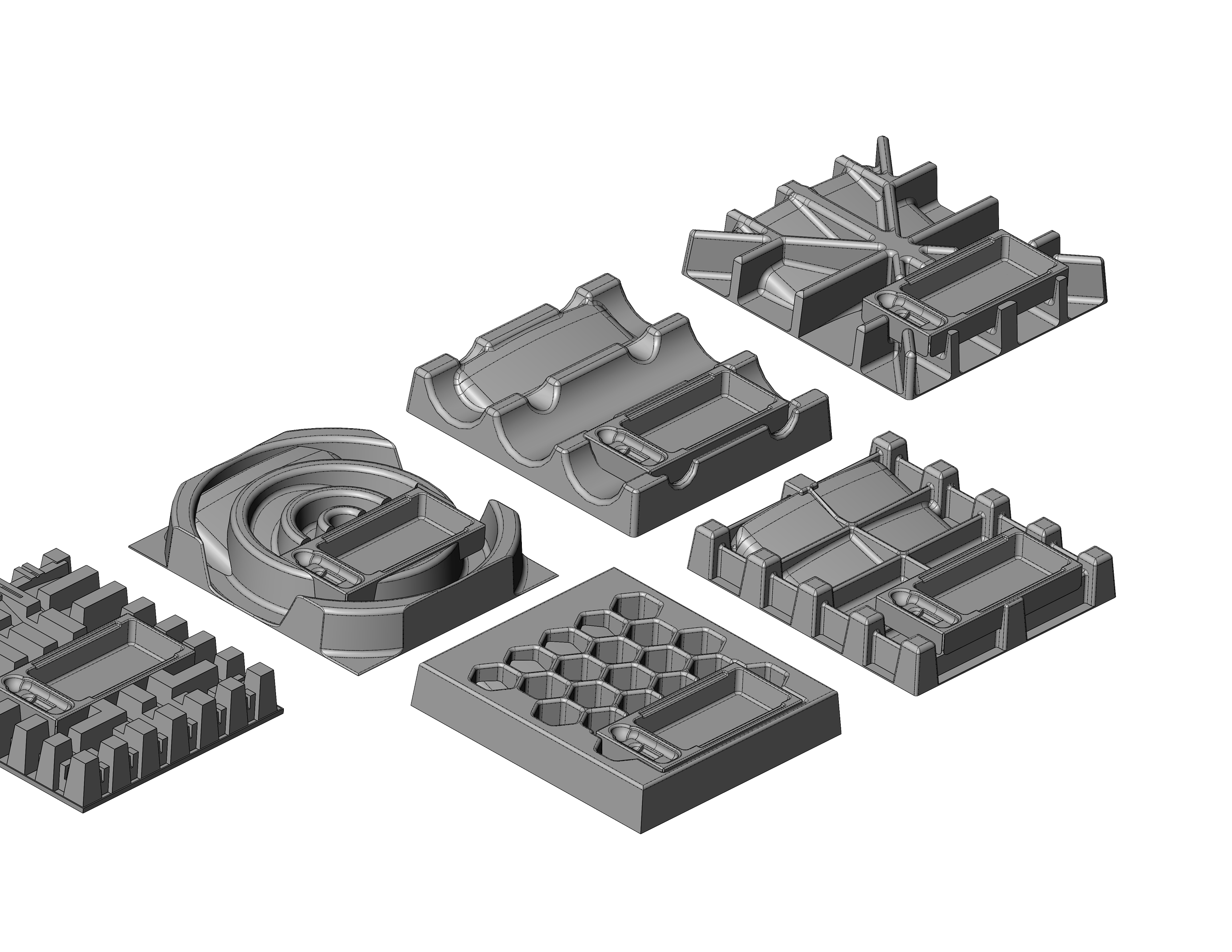

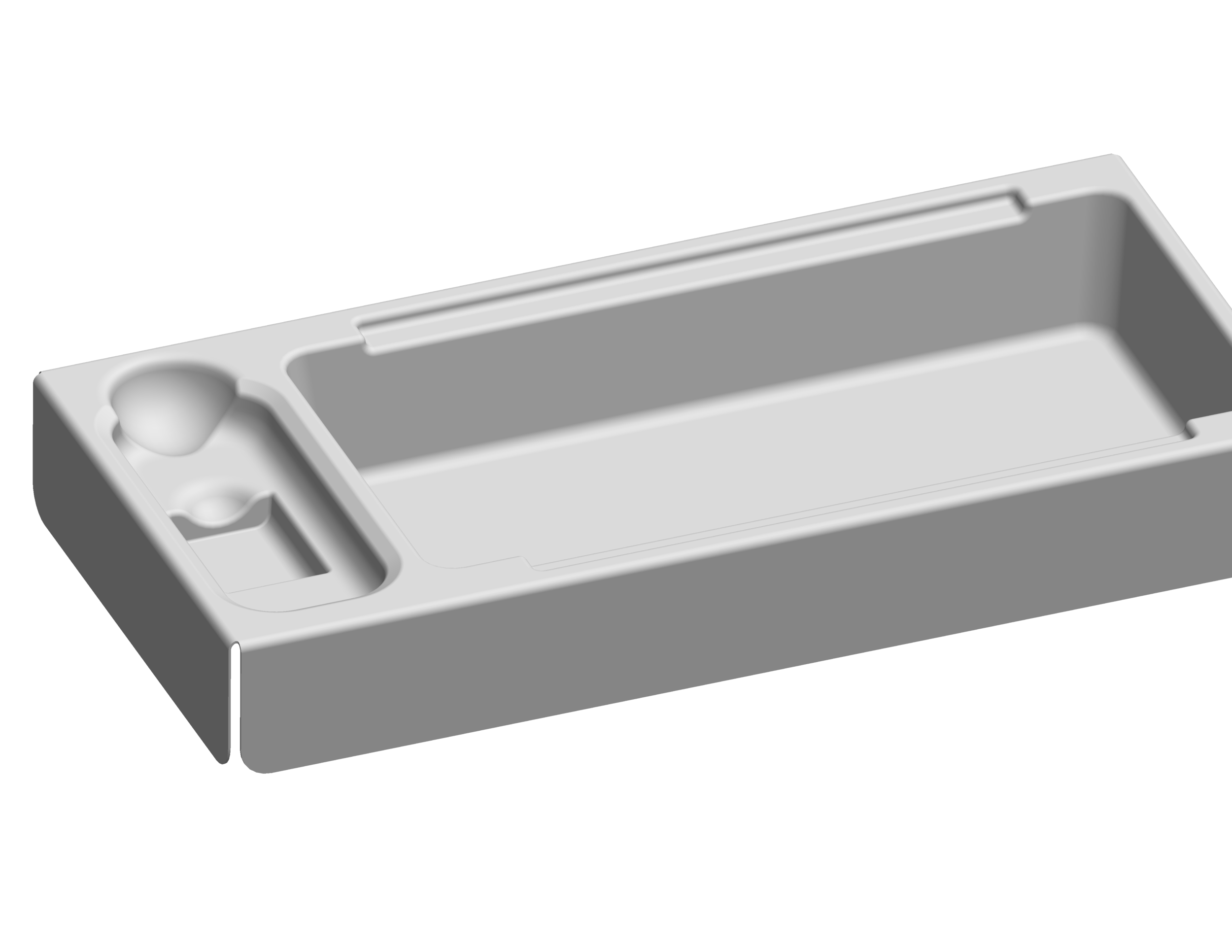

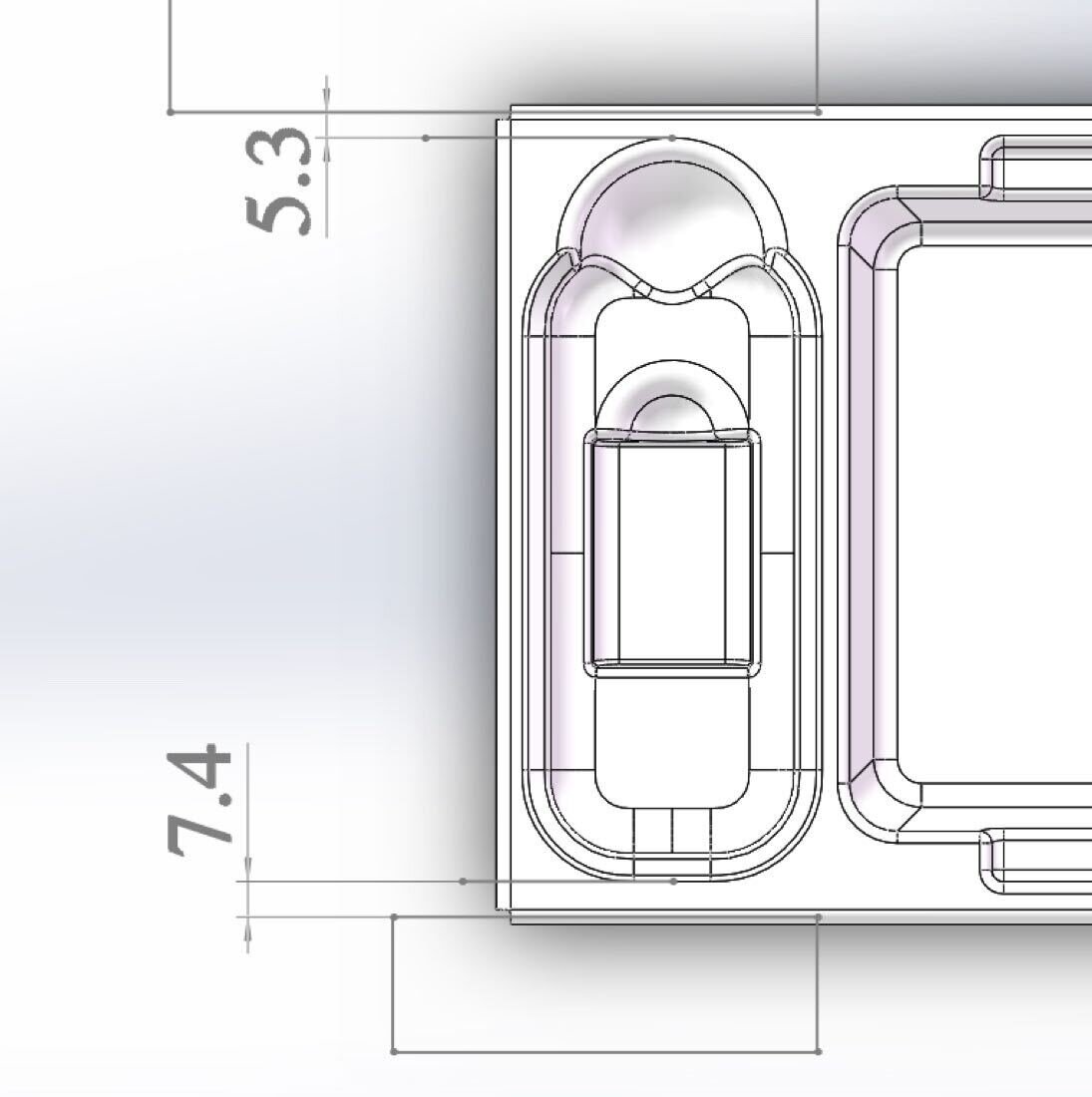

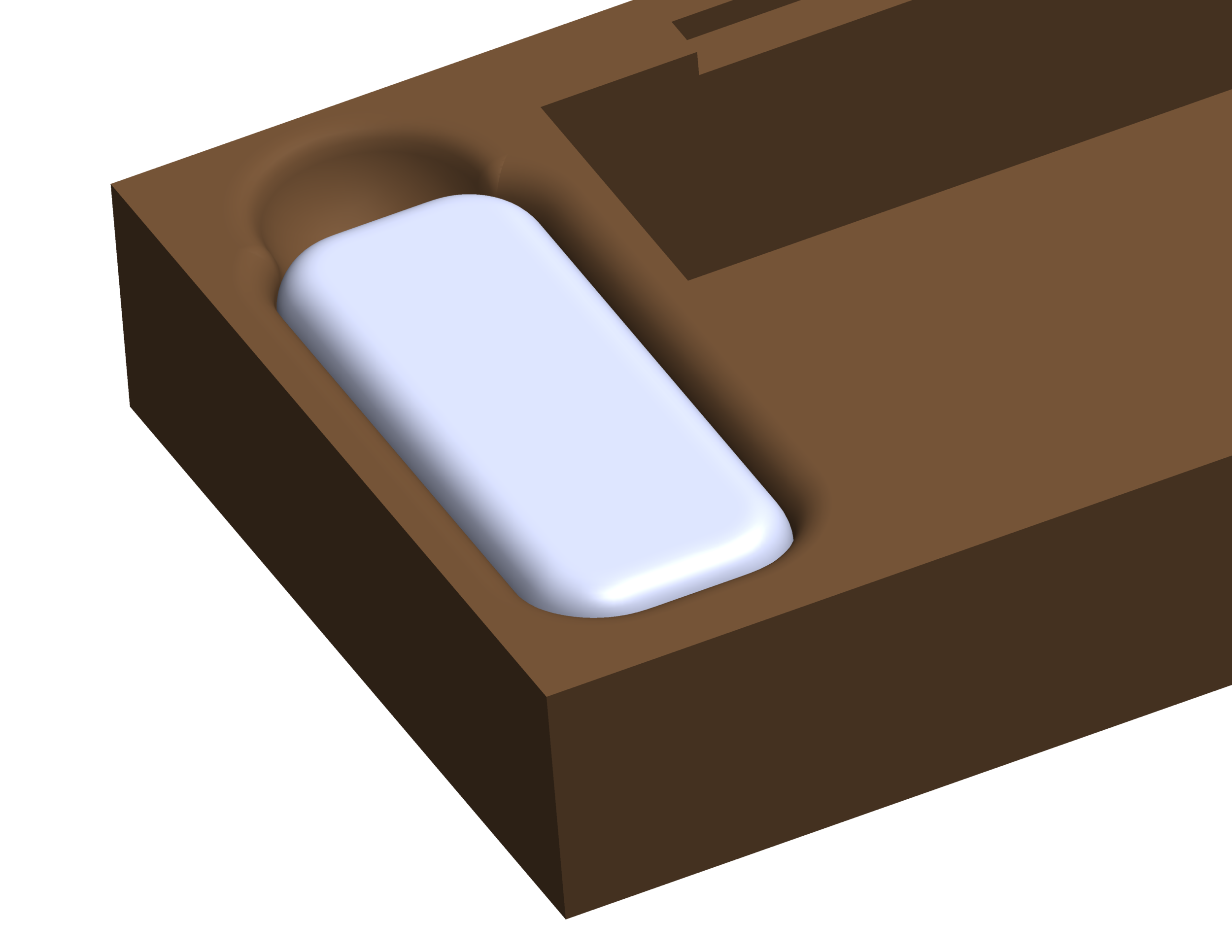

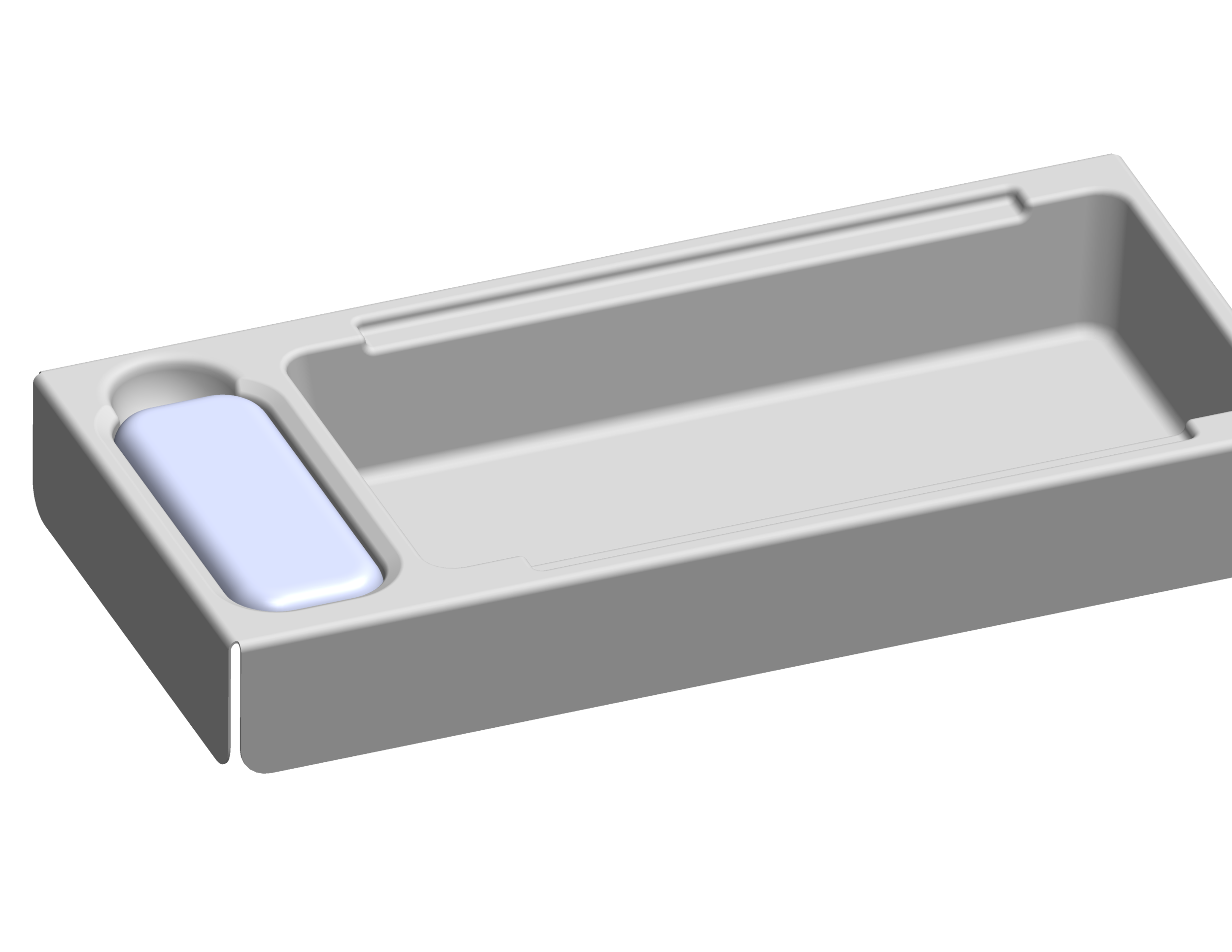

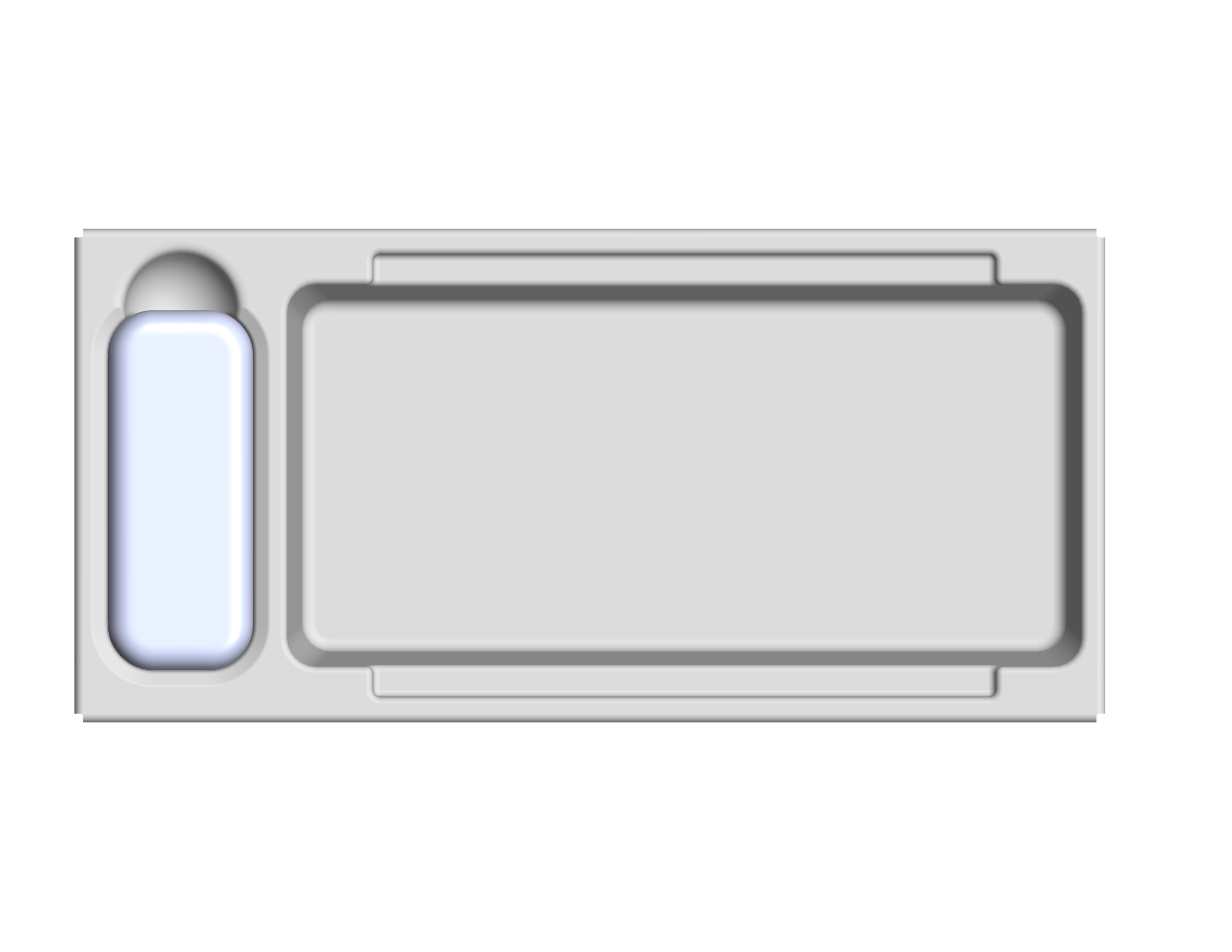

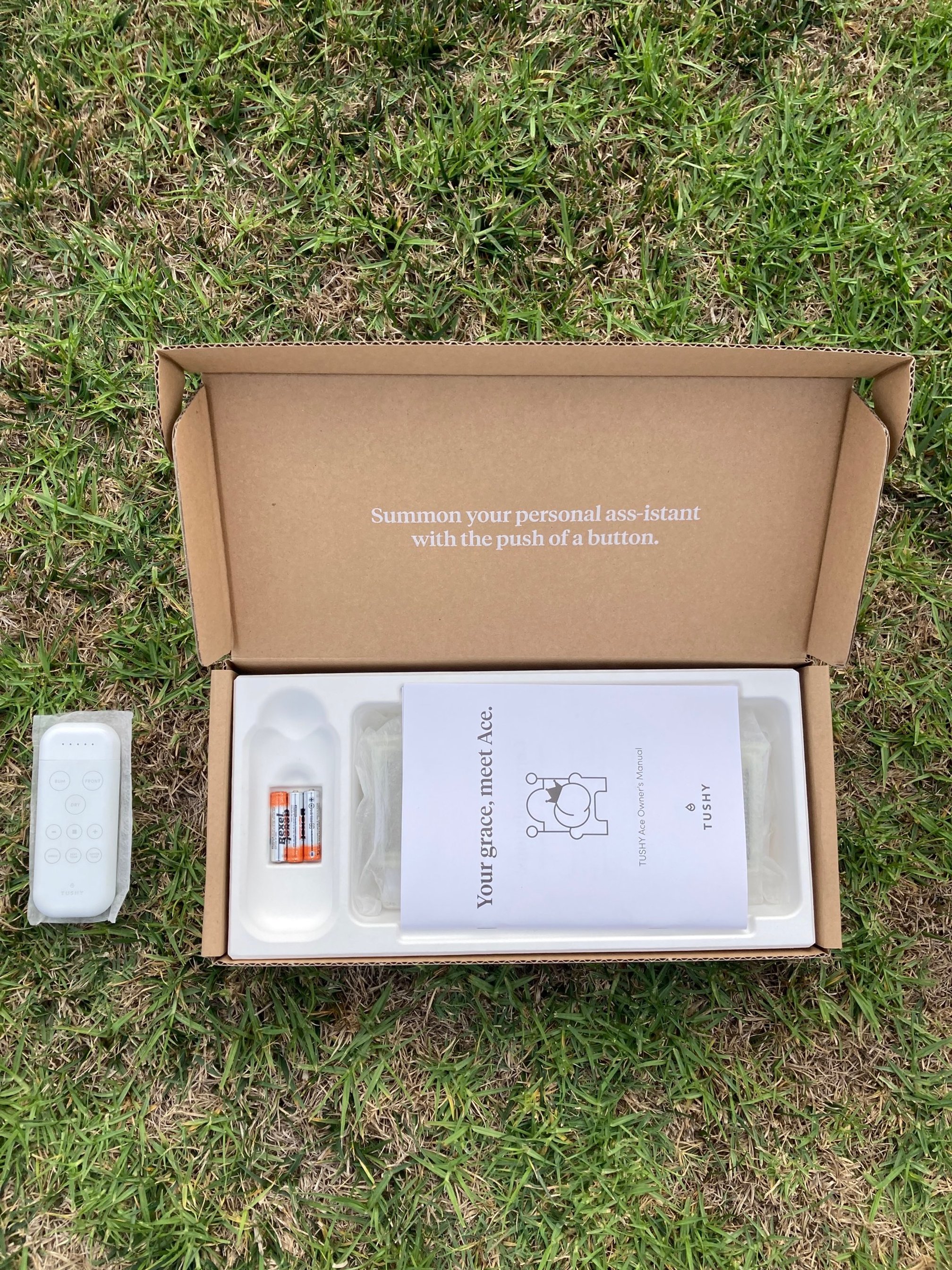

The next cosmetic adjustment was to protect the products accessories in a beautiful way. The crown jewel of the Ace is its stunning remote and as such deserved a throne. This throne was a molded pulp design with a cavity for the remote as well an adjacent well to hold the rest of the accessories. When given somebody else’s work, I take great responsibility in protecting its original intent. This intent was for a wet-pressed molded pulp design as it allows for the optimal surface quality, the issue is that is typically far more expensive. Considering this it was important to compare many different suppliers to achieve a reasonably priced, yet appealing product. After identifying the top candidate, I began working with the supplier to optimize our design for production which included adjusting the draft angles, fillets, and surface height. The most significant design change was the leveling of surfaces which allowed for the insert to be molded flat, saving greatly on tooling and production costs. The final material was 100% sugarcane pulp, allowing for compostability.

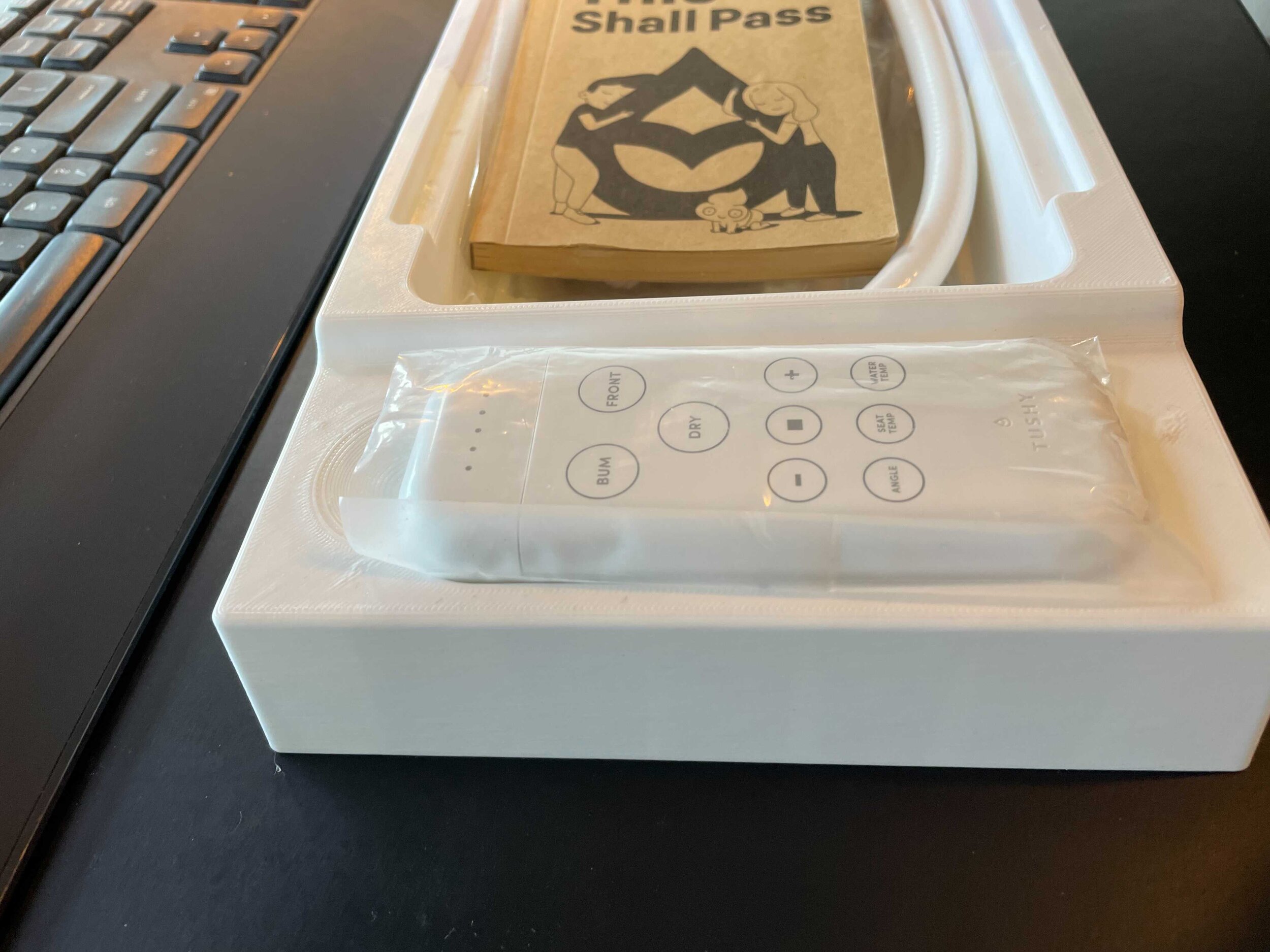

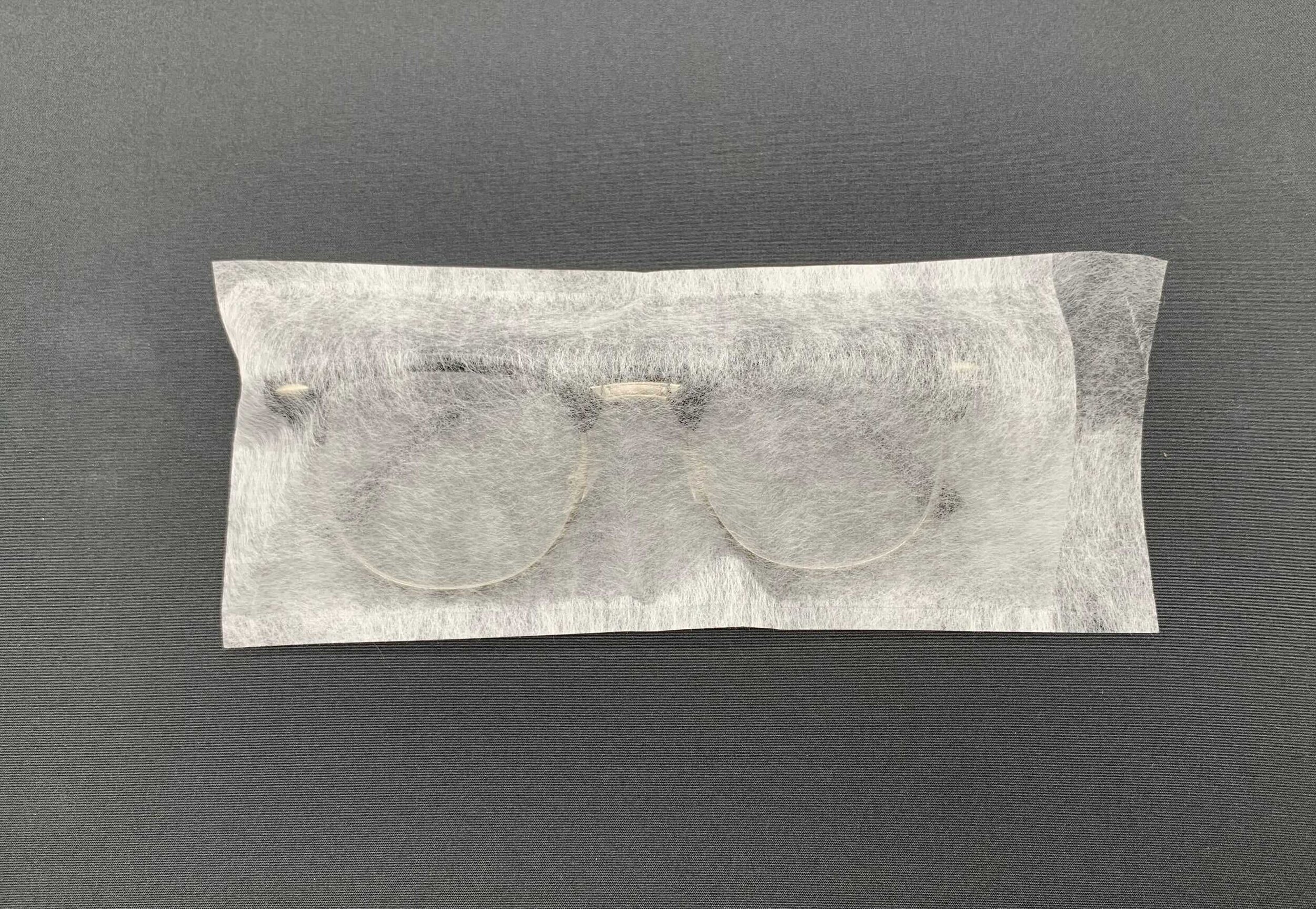

The remaining packaging deficiencies were a lack of an accessories bag and lack of scratch protection for the remote. As this molded pulp insert was beautiful, we did not want to tarnish the presentation with slapshot protection. I explored more bioplastic bags, paper bags, and lastly tea bags. Tea bags were of interest to me for their sleek look and sustainable materials: corn fiber. After talking with teabag suppliers, I found it was rare for them to produce custom sizes. I began researching other uses for corn fiber and sunglass sleeves were an application. Locating a supplier that produces these sunglass bags, I found they were able to produce our design to the appropriate specifications. After agreeing on negotiation terms for the accessories bag, the decision to use the same bag type to protect the remote was made. The flat bag dimensions were determined and validated. This consolidated our suppliers and maintained consistency within the unboxing presentation.

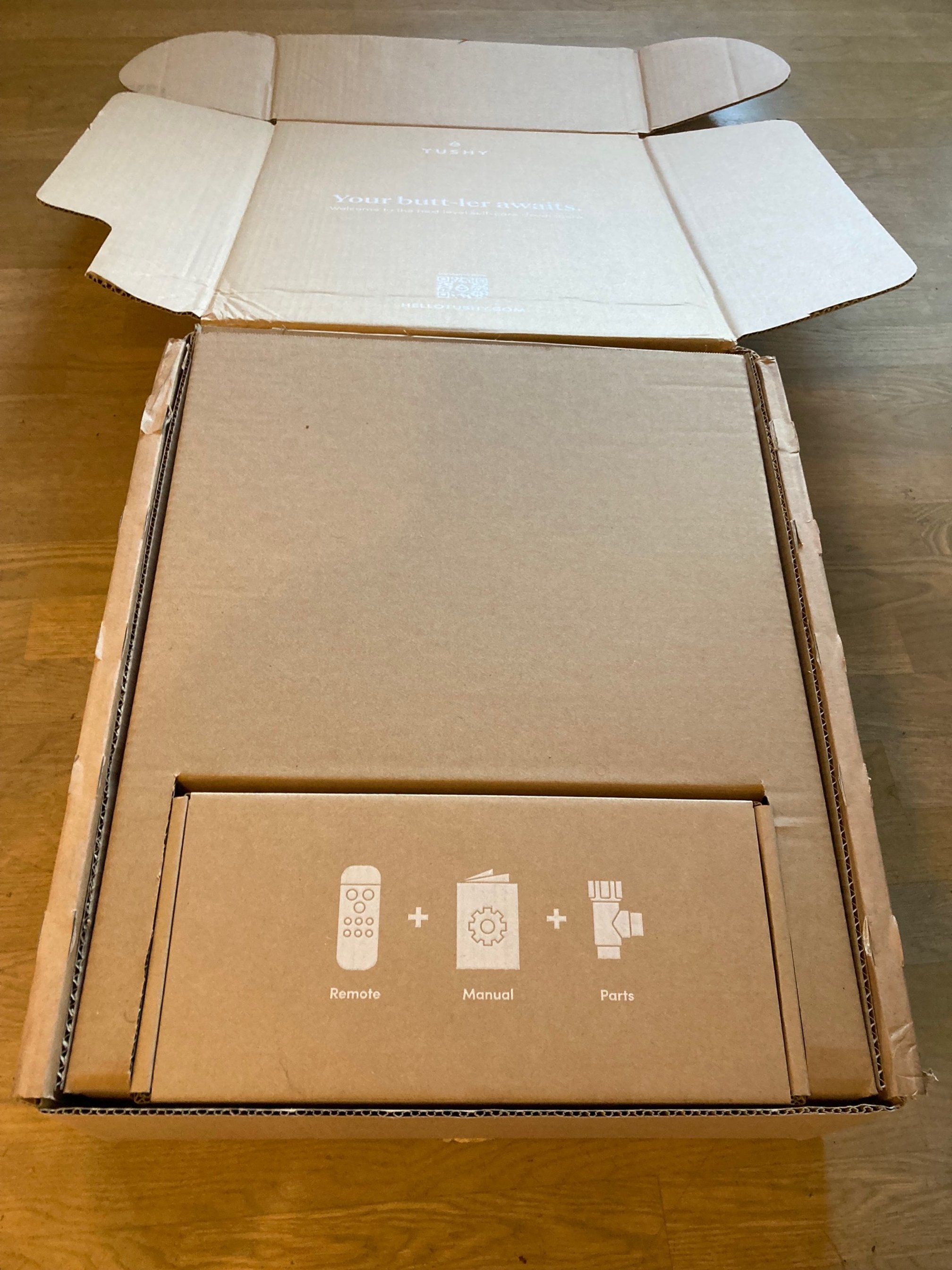

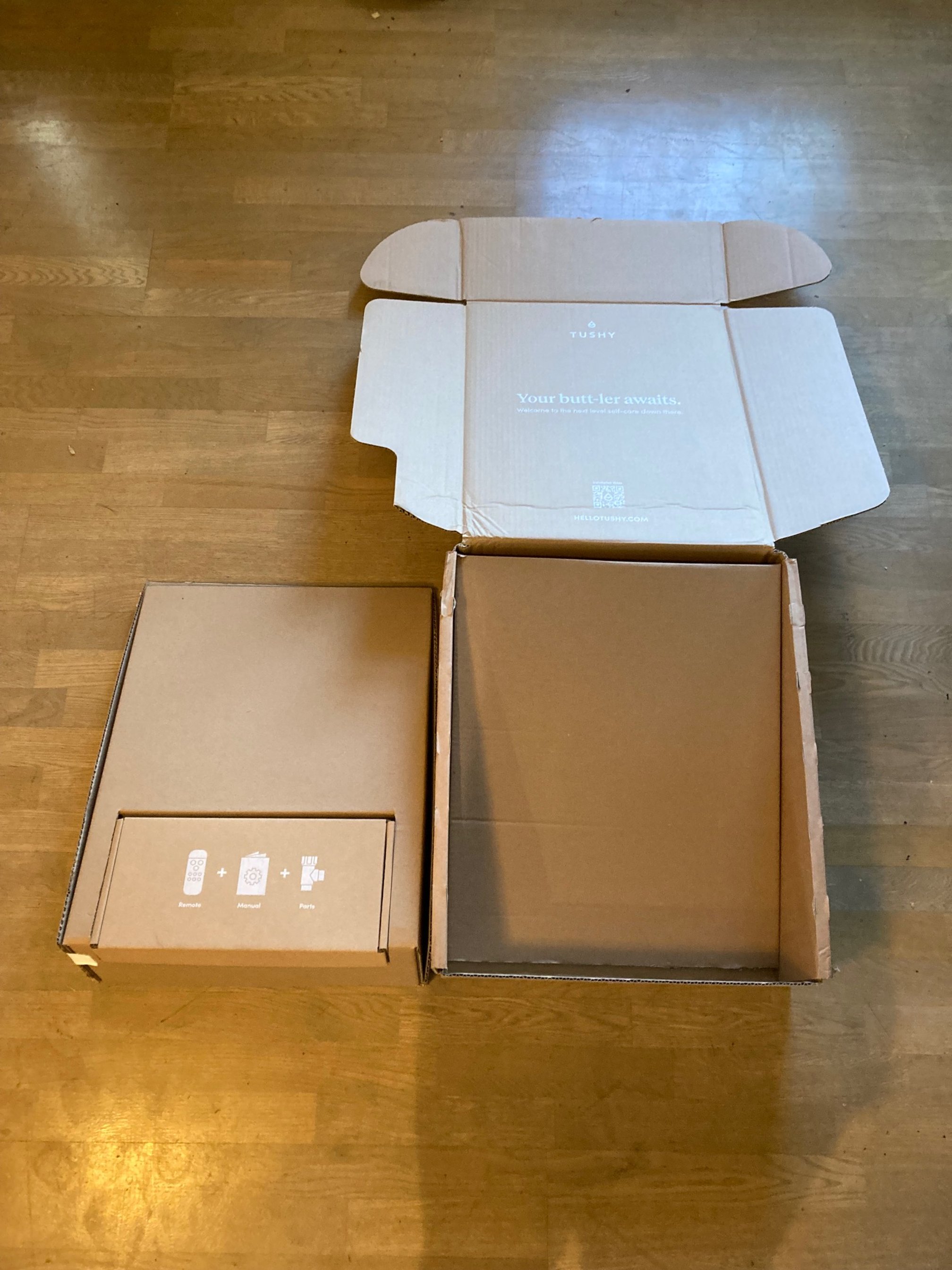

Unboxing

Bonus Alternative Designs

Molded Pulp

Triangular Corrugate